Probo, one of the largest printing houses for resellers in Europe, recently installed a new Zünd G3 L2-500.

Jordy de Jong, product owner and member of the marketing team and Mirko Vrielink, head of the technical team, explained what is happening at Probo in terms of production automation, marketing and development. ‘The innovation stream is virtually endless, and never stops. This means that every two weeks the workforce has to be briefed on ‘what it is, what it is used for and what can be produced with it’. Training, instruction and education are ongoing.’

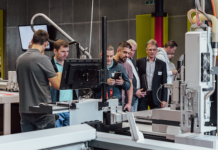

The training and instruction of employees on production lines is a particularly important aspect of Probo’s operations. Mirko Vrielink explained, ‘Together with Zünd, which has supplied us with a whole range of equipment for our production lines (currently 15 machines), we developed a system of training sessions involving the people in the factory to ensure that the systems are operated with maximum efficiency. We refer to some of these employees as ‘gurus’ because they have received intensive training and can instruct the operators on the different Zünd cutters, to ensure that ultimately the latter can work independently and solve problems themselves. We also use a job rotation system, giving employees an overview of our evolving production environment every week.’

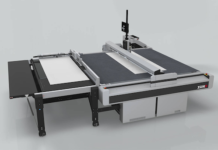

There are currently five production lines, four involving Zünd equipment. One line for through and kiss cutting foils currently includes 15 HP Latex printers. Zünd cutters are doing the Kiss-Cut-Work. Mirko Vrielink said, ‘This production line includes a new Zünd G3 L2-500. With the Centre Winder, the 2500mm long cutter and extra 2500mm cutter extension we can handle materials whilst the cutter continues to cut. The variety of jobs is such that we cannot really automate the unloading of the extra table. However, at the front end we can intelligently combine jobs, reducing the amount waste. The new Over Cutter Camera OCC from Zünd reads all registration marks in a flash and with the ICC camera we can read the necessary job information via QR codes. A second Zünd G3 L-2500 cutter will be added in due course.

|

LOCAL DISTRIBUTOR |