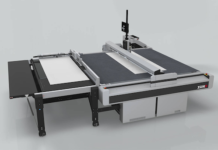

Lighting company Le Klint have expanded with a Zünd G3 XL-3200 with a conveyor feed and extension table, which features cutting and creasing tools for processing thin plastic and paper materials for their lamps and for cutting custom packaging in cardboard, foam and silicone.

Folding lampshades require expertise and in-depth knowledge of materials and techniques. When a series of products is mass-produced, die-cutting machines are mostly used. But for products that are under development, are in limited editions or are very large, Le Klint use Zünd cutters. Le Klint bought their first Zünd digital cutter in 2005: a Zünd LR-1600 with conveyor feed and extension table for continuous production from a roll. An automatic sheet feeder was later added to the machine, when they introduced ‘Swirl’, a new lamp-series, cut in thin plastic sheets.

Le Klint is situated in Odense, Denmark, and has since 1943 produced designer-lamps. Well known foremost for advanced folded and pleated paper and plastic lamp shades, Le Klint also works with other materials such as glass, metal and wood, and produces all kinds of lamps: pendants, wall lamps, ceiling lamps, floor lamps, etc. Creativity, beauty and craftsmanship are at the centre of everything Le Klint does.

Lars Kirkebæk Madsen, production manager at Le Klint, explained: ‘When you discover that your cutting machine can do much more than you initially had intended, you use it more and more. For instance, we now also cut packaging in cardboard and gaskets in silicone. Previously we bought these things ready-made. Every day, we evaluate what we need or things we miss, and our cutters are put to work.’

‘We bought our first Zünd cutter 15 years ago. It was acquired primarily to produce oversized lampshades that were too large for our traditional die-cut machines. These are machines where you make a roller in brass, which then shapes all the lines. Our traditional way of producing shades was also giving us developmental challenges, as we had to make a brass roller for each new shade, which was very expensive, especially if you had to make changes and adjustments to the rollers.’

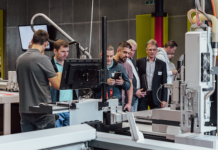

We came across a digital cutter at our packaging supplier, and that was just what we needed. So we invested in one similar, a Zünd Cutter. It did not take long before we started using it for many other things as well. We found that instead of punching holes in the screens by hand, we could use the Zünd cutter. This is the reason why we bought one more cutter. We use it not only for development, not only for oversized shades, but for lots of other things as well.’

‘When we work with designers, we are now able to produce models based on their drawings in short time, so our employees can start folding, and we can decide on adjustments. In a single work-day, we can create several variants of a new design and quickly decide on the further course. This was virtually impossible in the past. For each new idea or design, a brass roller had to be made by hand. Now it just requires that we have a digital drawing so that we can create a new product.’

‘Some of Le Klint’s lampshades, e.g. Caleo, have markings printed in the crease-lines. It creates a beautiful effect but requires very precise creasing. We plan to use the new optical camera for this. It can correct for minor tolerances, and ensure that the cutter creases precisely in the print,’ added Kirkebæk Madsen.

|

LOCAL DISTRIBUTOR |