We Are Lasers, a division of Traceability Solutions, has announced the new Kern LaserCELL and Epilog G2 Galvo Laser.

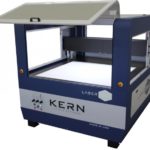

Kern LaserCELL

Following the great success of the flagship HSE laser, Kern has designed a Class 1 (safety enclosure) machine design, ensuring personnel working on or around the system are kept safe while the system is in operation.

The Class 1 safety enclosure is the ideal system to be placed in high traffic areas such as busy factory floors and university classrooms. Access points are available at the front, back and each side of the machine making part loading and maintenance simple and convenient.

Kern has redesigned the LaserCELL’s motion system, transforming it into its fastest and most productive machine to date. An improved down draft vacuum table is built into the system, allowing for consistent fume removal and material hold down over the entire 1320mm (52”) x 1270mm (50”) table. Lasers from 50 to 400 watts can be placed onto the LaserCELL system.

The Pipe Rotary, K-Vision Camera Registration and Metal Cutting system options are all compatible with the LaserCELL equipment.

Standard Features:

• High Performance Computer and LCD Monitor.

• Closed Loop Chiller (100W and greater).

• Exhaust Blowers/downdraft vacuum bed.

• High speed servo motors.

• 6.35cm (2.5”) FL Optics Assembly.

• KCAM Laser Software.

• CorelDRAW or AutoCAD LT.

• Laser safety kit.

• Laser tool kit.

Epilog G2 Galvo Laser

The G2 Galvo Laser is the first galvo laser system that can laser mark over a large work area without compromising engraving quality or requiring product indexing. The air-cooled, pulsed fiber laser engraves at remarkably fast speeds. Using a unique dynamic-focus lens technology, the G2 allows you to easily change your engraving area from 101 x 101mm (4” x 4”) to 406 x 406mm (16” x 16”) to 609 x 609mm (24” x 24”). Directly engrave into most metals and mark engineered plastics with speeds of 2m/sec and the added benefit of louvered ventilation for optimised airflow at any table height.

Product Details:

• Laser Source: Fibre Laser.

• Work Area: 609 x 609 mm (24” x 24”).

• Fibre Wattages: 20, 30 or 50 watts.

• Materials: directly engrave into most metals and mark engineered plastics.

Product Features:

• Marking Speeds of 2m/sec: dual-pivoting mirrors make microscopic adjustments to direct the laser beam to the table for incredibly fast, high-resolution engraving.

· Seamless Software Integration: print to the laser directly from almost any Windows-based software package including AutoCAD, SolidWorks, barcoding and serialisation software, or even graphics programs like CorelDRAW and Illustrator.

| LOCAL DISTRIBUTOR Traceability Solutions Tel: 0117044744 Email: michelle@wearelasers.co.za Website: http://www.wearelasers.co.za |