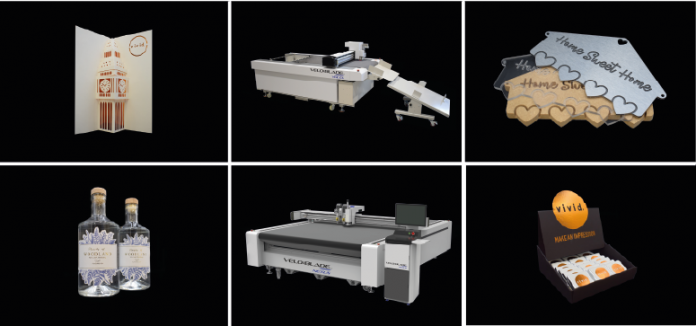

Vivid has expanded its digital die cutting offering by introducing two new ranges, VeloBlade Volta and VeloBlade Nexus. VeloBlade Volta gives users the ability to cut anything from kiss cut labels up to 10mm thickness, whereas VeloBlade Nexus is a range of wide format digital die cutters comprising an optional CNC Router for cuts up to 25mm.

VeloBlade Volta

Available in two sizes, 600mm x 400mm and 600mm x 900mm, the Volta range comprises four systems; VeloBlade Volta 64, VeloBlade Volta 69, VeloBlade Volta 64+ and VeloBlade Volta 69+. The key difference in these systems is that the + range has a cut depth of up to 10mm with optional oscillating tool, whereas the standard Volta 64 and 69 cut up to 2mm.

All of these systems give users the ability to completely automate their production. With 150mm of auto-feed sheet capacity as well as roll fed functionality, the Volta systems are designed to give users the best possible finishes, efficiently and cost-effectively. The fully automated workflow provides exactly that with its barcode reader, meaning Volta will even support multiple jobs at once, freeing operators up to work on other projects.

With a selection of tools that enable users to create unique and intricate products, without the expensive costs of traditional dies, VeloBlade Volta gives businesses the freedom to create by enabling them to work with stocks such as label, paper, card, KT board, Foamex and much more.

VeloBlade Nexus

Wide format print finishing has increased in demand during the pandemic. Starting from 1800mm x 1600mm and comprising numerous larger systems, VeloBlade Nexus opens doors of opportunity within the wide format industry.

Compared with the rest of the VeloBalde range, VeloBlade Nexus provides its users with the opportunity to work with the widest variety of stocks, thanks to its CNC Router being able to cut up to 25mm. These substrates include Dibond, MDF, fabrics, acrylic and much more. Also, you can still produce everything you would with the Volta range, the cut is that intricate and accurate.

Another feature the Nexus boasts is its automatic cut depth setting. This drastically increases setup and operating speed, making the operator’s job easier and more efficient. Efficiency was one of the key considerations when this system was put together, also contributing to an efficient workplace is the rotating bed that enables roll and sheetfed production.