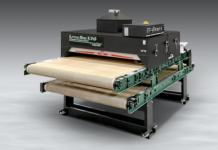

The LittleRed X1D Dryer, which can cure up to 29 garments per hour DTG-printed with digital white ink at 2 minutes dwell time, is now available with a 76cm wide conveyor belt.

By curing DTG-printed garments in an infrared conveyor dryer, the garments avoid the flattened, ironed-on appearance and halo associated with heat-pressing of printed images. The product has a 61cm wide heater, as well as screen-printed garments at rates to 65 per hour for water-based ink or discharge, and 150 per hour for plastisols. The dryer can also be employed to dry the pretreatment, relegating the heat press to flattening of raised fibres prior to printing with a one second ‘touch’ per garment.

As standard, it is equipped with features found on the company’s larger DTG-capable dryers including adjustable belt-to-heater clearance to accommodate bulky items, a dual digital PID temperature controller accurate to 1°C, and an X-Series conveyor belt roller tracking system with Teflon-coated fibreglass belt. A powered exhaust removes moisture and air contaminants at a rate of 5 CMM, while cooling the housing and controls.

The heaters of all Vastex dryers carry a 15-year warranty, and feature closely spaced coils that provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under curing associated with conventional units. Fully expandable, the X1D-30 can accommodate additional heating chambers and belt extensions as business needs grow.

Submit your news and video content to journo@practicalpublishing.co.za

Subscribe to our YouTube channel, read the top 5 stories weekly on WhatsApp or sign up to our newsletter.

|

LOCAL DISTRIBUTOR |