According to Dr. Nicholas Hellmuth, writing for FLAAR Reports, textile printing is still a growing trend, in part because there are five different kinds of textile inks and many different kinds (structures) of wide format inkjet printers to handle printing on fabrics. If you wish to enjoy the literally largest textile printer expo in the world (for brands from EU and Asia together), then ITMA is the king. Let’s explore textile printer options, starting with size and production speeds as well as textile trends.

The textile printer research manager of FLAAR-Reports, Maria Renee Ayau, is attending the Sign Africa and FESPA Africa expo to write about UV-curing printers, flatbed cutters, laminators, inks of all kinds, and printable materials for multiple applications. Plus this annual event has a great area for T-shirt printers that she will enjoy visiting. Read about her report in the next issue of Sign Africa Journal.

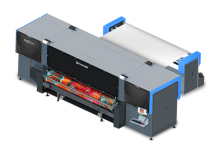

Single-Pass Textile Printers

Everyone says ‘single-pass is the future of inkjet printing’ but no ‘Mom and Pop’ (friendly family business) in a mall area has space or money for a single-pass printer. More realistic short-term popularity will be entry-level with high-end accessories: a feeding mechanism for giant heavy rolls and huge ink tanks (to significantly lower ink cost from outdated horizontal or vertical cartridges).

Because of the size and weight of a single-pass printer, whether for glass, ceramics, packaging, or textiles, at most expo’s, these enormous printers are ‘exhibited’ only in brochures and a photograph on the wall. Examples were the EFI Reggiani BOLT and the PIKE in the large booth of SPGPrints.

Heavy-Weight With Complete Workflow

Mid-Range Textile Printers

Two nice examples of mid-range printers were in ColorJet’s booth. They introduced their Vastrajet 8164 printing direct-to-fabric. Their Metro 8166 was available to print with reactive dye ink. I visited the impressive world headquarters of ColorJet in India a few weeks before ITMA. They also make UV-curing flatbed printers.

DGI, JHF, Homer had printers as well. We had earlier done print samples on JHF textile printers at FESPA 2019 in Germany. JHF is expanding worldwide both in UV-curing and now in textile printers. We have been to the JHF factory and headquarters outside Beijing many years ago.

Entry Towards Mid-Range

The printers in this classification are either wider or based on more years experience in the textile printing world (so they are definitely not low-bid).

d.gen had a wide range of nice textile printers in a booth on a corner (which means you could see the booth from two aisles). Optimum Digital Planet had two productive mid-range printers – fully functional.

Entry-Level: For First Time Users

The HP Stitch models are being showcased at the Sign Africa and FESPA Africa Expo in Johannesburg.

Entry-Level: With Added Features

I classify entry level in several stages: there are nice textile printers, engineered in Japan, but they are designed to be at a price to appeal to first-time users. There was not one single booth of any of these Japanese brands for first time users. Mimaki was the only brand that had an entire booth that featured entry-level and upper-level mid-range textile printers (from La Meccanica, the Italian company that Mimaki recently acquired).

Low-Bid Entry-Level

Nowadays you see solvent printers that have the frames to hold UV-LED curing lamps on each side of the print head carriage. This is because these carriages are mass produced to serve for whatever ink the manufacturer decides to stick in the ink system. 15 years ago, UV-curing printers were solvent printers with the UV features barely tacked on. The same with textile printers in the early years: they were just solvent printers with a different ink (mostly because the low-end manufacturers had no experience with handling textile material).

I can still remember an international brand, made in Japan, and the first year they launched a textile printer there was no transfer paper calender machine in the booth. Plus none of the sales reps, and most of the booth personnel, had no idea about textile inks, or what kind of rollers were needed to keep the fabric from creasing as it fed from the main roll, through the printing area and was gathered up on the other side. These are the aspects that define low-bid entry-level: the companies do not come from the heritage of textiles nor textile inks nor workflow experience.

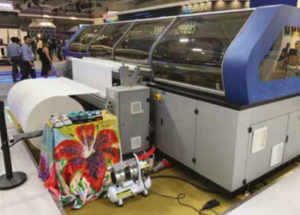

Direct To Fabric Compared To Printing On Transfer Paper

For direct-to-fabric, you need a dye sublimation unit, but these are almost always physically attached to the front of the printer. For printing on transfer paper, this requires a calender machine to take the paper and sublimate it onto the polyester fabric. Several brands that were using transfer paper had a calendering unit in the booth but most did not have accessory curing equipment (because the calendering unit is a different brand than the printer). But it is helpful to the end-user to show the entire workflow.

I noticed 14 brands of transfer paper (far more than I expected). The large quantity of brands was because companies that make traditional signage materials (like Felix Schoeller) realise that market share is moving towards transfer paper. But several transfer paper brands were missing from ITMA 2019. You should be able to find these at FESPA 2020 in Madrid.

Nine brands of calendering machines were evident: Klieverik and Monti Antonio are international brands and they will also be at FESPA events around the world.

Printheads

Fujifilm Dimatix has higher percentage of the high-end textile printer market than they do in the UV-curing printer market. For example, Samba heads are used in single-pass printers.

Kyocera is king for mid-level and high-end. If the price of the printhead goes down in the future, Kyocera will definitely be the number one print head for textile ink printers around the world.

RICOH Gen5 heads are in a few textile printers (but are more common in UV-curing printers). Same with Konica Minolta print heads: lots in UV-curing printers but outside their own Konica Minolta booth, not many printers used these heads for textile inks at ITMA.

Textile Inks

A trend that you would notice quickly as you visited lots of printer booths is more and more printer manufacturers are trying to let you put different kinds of ink into the same physical printer. But realise that for most of these, you have to select your ink upfront, and then you can’t change it (since every kind of ink requires different delivery system). Plus if you change from one kind of ink to another, you have to flush out every millilitre of the first ink: this wears out your printheads.

So Mimaki was innovative in offering a printer that had two ink systems built into the printer from the ground up: the Mimaki TX300P-1800. With this one single printer, users can print direct-to-transfer paper (to be sublimated on a calendering machine) or direct-to-fabric (to be sublimated in front of the printer). Mimaki even cleverly has a platen for both paper, and a platen that can drain direct-to-fabric ink into a drain (since printing on the actual fabric means that some ink will leak through the weave).

RIP Software For Printing On Textiles

Three RIP companies have extensive experience in making software for printing on fabrics. All other RIP brands have scurried to add a textile segment to their signage RIPs. If you are going to be 100% textile focused, then it will definitely be more realistic to have a RIP software from a company that has been working with textile inkjet for over a decade. If you have 10 different kinds and different brands of printers in-house, it is understandable that you prefer to stick with the same original brand of RIP that your UV-curing or solvent printers already have.

Textile Design Software

It was a nice surprise to see an Adobe booth at ITMA. Their booth is an excellent example how a totally non-textile company has recognised the growth potential of digital printing of textiles. Their new software is called Adobe Textile Designer. This was coordinated with Datacolor’s ColorReaderPro.

Colour Management

Colour management involves software and spectrophotometers. There are brands that everyone knows and uses and there is a single brand that focuses on being able to handle lots more than just signage materials. A good option is Barbieri, since they’ve handled textiles now for many years, although X-rite is also a respected brand from the world of signage printing.

Workflow: Pre-Print Sprayers, Heaters, Cutters

Every kind of ink either needs, or does not need, pre-treatment or post-printing treatment. You get what you pay for. Reactive dye ink and acid dye ink need the most pre- and post-treatment accessory equipment. I can still remember visiting a textile printer training centre that showed the entire process in-situ, actually being used as a commercial print shop. The space needed was endless and the number of operators was considerable. This is why a lot of print shops prefer using pigment ink (even with its limitations, such as primarily on cotton and only a few other materials).

The primary workflow equipment actually on exhibit at ITMA was for high-end printers. Mimaki showed steaming workflow equipment from the Australian company they acquired recently. Mimaki is definitely investing in the textile trend (and in more than just the printers: printers need pre- and post-printing equipment). Zimmer also is advanced in this category.

But otherwise, most printer brands want your budget for their printer; not for the needed workflow items (those you find out about after you buy the printer).

Reality Check: Print Issues In Photos With Shadow Areas

In most cases, photographs print better with water-based pigment inks on a traditional giclee or photo printer (Canon, HP, etc.) Although we printed photographs nicely at ITMA on an Optimum Digital Planet printer and on d.gen textile printers, I would recommend printing line art rather than photos on fabrics. One reason is because anything in a shadow area of a photograph may not reproduce well on a low-end textile printer (or when you don’t do colour management, ink load, etc). But do realise that some kinds of illustrations will look better on solid materials rather than on woven materials.

Often it’s the ink, while in a few cases it’s the brand of printhead (for backlit especially). But often it’s because most print shops don’t take the time or investment to have high-quality colour management tools and software that can handle textile prints.

Reality Check: Some Colours Print Beautifully, Others Are Dull And Uninspiring

Every kind of ink is good at some colours, spectacular at others, but inadequate for others. For UV-cured inks, 50% of printers and inks can’t handle yellow adequately – it’s either too green or too ‘dirty’ or too uninspiring in another manner. In past years, oranges and especially reds were tough to reproduce. Some blues and other colours are oversaturated in UV (though that is as much a lack of colour management as it is of being UV-curing ink).

Reality Check: Dye Inks Fade; Pigment Ink Holds Up

20 years ago, everyone said that only dye inks had full colour pop. But I have images printed with ColorSpan and HP printers of 18 years ago with pigment ink. The prints have gotten sun from the tropical area of Guatemala, Central America all through these 18 years. The colours of these pigment inks are gorgeous still today. The photos are not outside, but they are on walls inside our office that get sunshine coming in every day (except perhaps in the monsoon rainy season of cloudy weather).

Almost everyone today says ‘pigment textile ink is not as colourful as dye’ (sublimation or other textile inks all of which are dye-based). Yet year by year, pigment inks for fabrics have more colour (especially if you have a professional colour management software and textile-capable spectrophotometer). Plus the appearance of the colours depends as much on the surface of the fabric as it does on the chemicals within the ink (since some fabrics have a dull appearance and other fabrics are bright and shiny even without ink on them). If you wish to see how colourful a textile ink can be, just explore printers in a Kornit booth.

Advantages Of Using Textiles To Print Photos

Nowadays, for signage, fabrics are great for backlit. But we print panorama photos on textiles both to test the printer quality but mainly also because it is easier to move a photograph if it is printed on fabric than if printed on photo paper. A single ding will ruin the entire image if it’s on photo paper. But with textile, you can roll them, fold them, or simply toss the mass of fabric into your suitcase or backpack and carry them to any trade show or exhibit. Plus fabric weighs significantly less than PVC vinyl.

Submit your news and video content to journo@practicalpublishing.co.za

Subscribe to our YouTube channel, read the top 5 stories weekly on WhatsApp or sign up to our newsletter.

FLAAR REPORTS www.flaar-reports.org