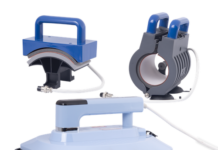

The TURBO wrapper redefines every step of mug production, by using two separate parts for wrapping: a wrap with stainless-steel rods and a stainless-steel clamp.

The wrapper uses a double camshaft system. The first cam will pre-stretch the wrap and position the transfer paper to the mug body. The second cam then closes the wrap around the mug body. Aligning of the transfer paper is done by placing the paper within adjustable brass pins to fit various paper dimensions. No tape is required, which ultimately limits the possibility of wrong alignment. The wrapping process is completed in a single fluid motion and requires no training or exceptional physical strength.