Using an exposure calculator correctly will help the stencil last longer and hold the detail that the emulsion is capable of. There are several exposure calculators available, the one I will explain has five target areas and is used for Diazo and Dual Exposing emulsions only.

Please refer to the images above the article that correspond to the headings of each section below.

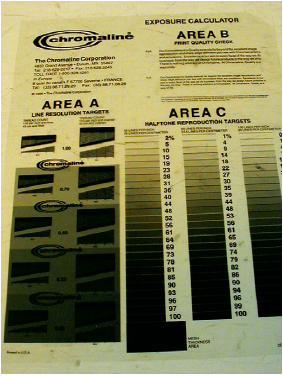

Exposure calculator

The first target area is clear and has a factor of '1.0', meaning it gets the full amount of UV rays emitted by the exposing unit. The target area next to that has a light tint and a factor of '.70', which means it allows 70% of the UV rays through it.

Close-up of filters

The next three filters get progressively darker and have factors of '.50', '.33' and '.25' which means they allow 50%, 33% and 25% of the UV rays.

Exposed screen

The calculator is put on a coated screen and exposed for twice as long as seems necessary. Diazo and Dual Exposing emulsions change colour when exposed. For example, an emulsion that is blue prior to having sensitiser added will turn green from the sensitiser because the sensitiser is a yellow ochre colour. Once it is fully exposed, it will turn dark blue. If any green is present other than in the image area, it is not fully exposed.

An emulsion that is lavender before it is sensitised will turn to a beige colour once sensitized and dark purple once exposed. The changing of the colour of the emulsion is what will let us determine whether a stencil is properly exposed or not. By exposing the stencil for twice as long as is thought correct, one of the target areas should have the correct exposure.

Calculator image on a wet exposed screen prior to full wash out

After the screen is exposed and wet, check the target areas starting with the one that allowed 25% of the UV rays through it. What you are looking for is the colour of the emulsion in the target area and the colour of the emulsion outside the target area to be the same colour, or very close to it.

Close-up of target area of wet screen

If all were correct, the target area that allowed 50% of the UV rays through it would be the first one that is the same colour as the area that didn’t have a filter. If this is so, then take the exposure time and multiply it by the exposure factor from that target area, '.50', and that would be the correct exposure for that particular mesh count, mesh colour, emulsion and coating technique. If the colour in the target area is lighter that the area outside the target area, then check the 70% target area. If that one is also lighter in colour, a new test has to be conducted that is twice as long as the previous test.

Once that test is conducted, a correct exposure time should be determined. If none of the target areas are lighter than the area outside the target area, then all the areas are overexposed and the test needs to be conducted for half the amount of time.

This test needs to be conducted for every mesh count, mesh colour, emulsion and coating technique to determine proper exposure. Remember that coloured mesh requires approximately 50% longer exposures than white mesh.

This test should be done periodically and based on the number of screens exposed daily and whether or not there seems to be a breakdown problem when printing.

This article was published in the Practical Sign & Digital Graphics Magazine: www.signafrica.com/magazine.