Midcomp has installed a second HP Stitch S500 dye-sublimation printer at Zak Sport (trading as Diski Sports). The premium printer provides double the speed of Diski Sports’ other sublimation printers and offers unmatched quality. Diski Sports also opted for Midcomp’s world-first Pay Per Use (PPU) and PPUGRO® programmes, which give the company peace of mind and cost savings. This is a sponsored article.

The S500 is an all-in-one dye-sublimation solution. With a single device, you can print on both transfer paper and direct to fabric with great results. Get reliable image quality with 2 x CMYK user-replaceable printheads and automatic compensation of up to 30% nozzles out. Without increasing production space, you can double your unattended printing capacity. You can also efficiently manage your fleet, and remotely monitor printer status and ink/substrate use with HP PrintOS.

Midcomp is not only a large format printing and finishing equipment supplier, they are experts in their field, and their extensive service offering, support and world-first Pay Per Use programmes are testimony to the high levels of expertise within the organisation.

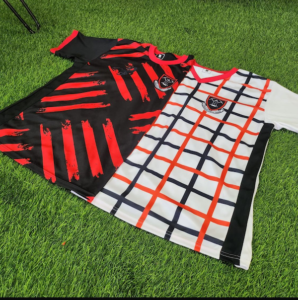

Diski Sports specialises in branded sportswear, custom dye sublimation sportswear and sports equipment. Its range encompasses all types of sports including football, rugby, volleyball, netball and basketball. The company supply sports kits and sporting equipment for various schools, universities and sports clubs. Its in-house branding department offers custom branding for banners, flyers, T-shirt printing, posters, dome stickers, corporate gifts and corporate clothing. Services include a variety of branding options such as full colour heat transfers, embroidery and dye-sublimation.

Afzal Sibda, Production Manager at Diski Sports, explained, ‘We initially started off as a retail store business. We expanded from one store to five, only dealing in sportswear and it was more about selling the branded names and the branded items. Just prior to COVID, we started reducing our retail stores, and eventually decided to move out of the retail space and rather go into wholesale and manufacturing. We then shut down all the retail stores and created Diski Sports, which is a custom sportswear manufacturer.’

The first S500 was purchased just before the COVID lockdown of 2020, and the second was purchased midway through 2023, when the business realised that they needed to expand, as production was going well.

Midcomp showed Diski Sports a demonstration on the machine, and the company saw how it could benefit their business regarding sportswear manufacturing and custom sportswear.

Initially, the first S500 was purchased by the company outright on its own, as there was no Pay Per Use option at the time. ‘We were experiencing a lot of maintenance that needed to be done on the machine. The cost of constantly buying ink, running short on ink, ensuring inks were in stock, and ensuring the printheads were always up to standard as they affect print quality, was all becoming very expensive for us. Then Midcomp launched the PPU and PPUGRO® options. We looked into them and saw their benefits,’ said Sibda.

The PPU comprehensive and customised programme, created by Midcomp, helps accurately calculate a company’s costs per square metre. This ensures peace of mind that if something goes wrong with a machine, it can be fixed without having a huge bill to deal with.

The PPUGRO® solution offers a PPU Programme that gives customers the option of including a printing and finishing system as well as RIP Software, consumables (excluding media), service costs and insurance charged at a predetermined variable rate per square metre that the customer prints. At the end of every month, a customer will be sent a spreadsheet detailing the jobs they have printed in that month as well as the total square metres printed. Midcomp applies the variable rate per square metre and sends a customer one invoice.

With the first printer, the company switched over to PPU, giving them the benefit of always having consumables on hand, technical service and maintenance, all of which was being provided by Midcomp, ‘They are just a phone call or email away and they can get a technician out. So we get priority when it comes to services etc. because we have the PPU option,’ said Sibda.

When deciding to invest in the second printer, Diski Sports investigated the PPUGRO® option. ‘Midcomp explained to us how the package worked. We didn’t need to pay a big sum of money to purchase the machine. We went on to a PPUGRO® option where Midcomp supplied the machine and the Easty heat press all in one package,’ said Sibda. ‘We can better manage what our costs are on PPUGRO®. We have a set ‘per square metre’ charge, which we pay Midcomp for on a monthly basis.’ An Easty heat press was also provided in the package deal of the first S500.

Machine Features

According to Sibda, when the business decided to go into manufacturing, they were limited, and just took different coloured fabrics and stitched them together to make a product. The S500, however, enables them to offer fully customisable garments to their customers: ‘No two sports teams want to look the same. The S500 allows us to produce custom sublimated garments for every team that we work with.’

He added that the S500 is almost double the speed of the company’s other sublimation machines, and that the quality is unmatched. After extensive research, and considering all the machines that were available on the market, the business decided that HP is still number one when it comes to print speeds.

Sibda said that the main feature of the S500 is reliability, and he is confident that the business can take on certain jobs and not have breakdowns midway through.

New markets

The company initially only focused on sportswear, but according to Sibda, with the S500, there is a lot more that can be done, and they are now looking at gradually tapping into the promotional products market as well, such as branded gazebos, towels and tablecloths, ‘We have received requests for items other than sportswear, which we help customers with. We don’t say no (to jobs).’

Service

Sibda also praised the service from Midcomp: ‘We have no issues when it comes to service. The salesman is always our first point of contact, and we always have the technicians on standby to assist us. We also go through Midcomp for some of the consumables because they are very compatible when it comes to pricing in the market. Midcomp is always just a phone call or an email away.’

‘If there is something that needs more specific attention, they always send somebody out to come and see us. They understand the nature of our business, where everything is about tight deadlines. So if I urgently need a technician, they will try and accommodate that. If it’s something not so urgent, we just stick to the normal service level agreement. When we do have urgent queries, they’re always willing to assist us.’

|

LOCAL DISTRIBUTOR |