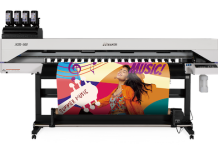

The SIJ-320UV specifically supports the needs of wide format print service providers in Africa, China, Taiwan, Russia, Korea, Southeast Asia, Eastern Europe, the Middle East and Latin America. These markets are slowly moving into the UV printing markets but don’t have the financial capabilities to buy an expensive printer. So, the SIJ-320UV is the ideal combination of a UV-LED roll-to-roll 3.2m printer at a very reasonable price, that can also print dual rolls at high resolution.

Since the printer’s launch at the FESPA Africa and Sign Africa expo in July, twelve machines have been sold. ‘The majority of sales made at FESPA Africa were from local customers who were previously using Latex or solvent printers as well as customers who always wanted a 3,2m production printer, but could never afford it,’ said Rob Franco, MD, Graphix Supply World.

‘This cutting-edge printer is half the price of its nearest rival, but offers double the speed at a higher resolution. The ability to print high resolution graphics at a low cost puts it within reach of any graphics or signage company.’

This printer is the first of its kind to offer the newest UV technology LED lighting that saves energy, something that is not always available in abundance in developing countries. The lamps last approximately 10 000 hours compared to Mercury Halide lamps that last 1000 hours. The device is also easy to work with; it is bundled with RIP soft ware and offers options for dual roll printing. Printers will be impressed with the 60sqm/h (max is higher) printing on banners in high quality.

The built-in quality and uninterrupted print run checking features combine perfectly with the newly developed LUS-120 high performance UV curing ink, enabling the printer to produce uninterrupted high quality, high speed printing of various signage media, including PVC and other banner materials. The machine can print to PVC, PET, paper, fabrics and any bun coated flexible solution.

MIMAKI’S UNIQUE QUALITY-CONTROL TECHNIQUES MAPS4—MIMAKI ADVANCED PASS SYSTEM 4

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven colour printing. To reduce such unwanted printing, Mimaki has developed MAPS. The SIJ-320UV is the world’s first printer that uses the latest MAPS4 technique, incorporating the most advanced algorithm for spattering boundaries between print swathes. Beautiful quality print outs are produced even in high-speed printing and lengthy printing operations. ‘At last, there is an affordable, high resolution, Japanese-engineered UV printer with the lowest print cost in its class,’ said Franco.

MFD1—MIMAKI FINE DIFFUSION 1

Dithering is an image processing technique that transforms image data for inkjet printing. Pattern and error-diffusion dithering may, however, generate particular image noise resulting in uneven colour printing or tone jumps, even on a high performance printing unit.

The newly developed RasterLink 6 soft ware, (1) incorporating the patented (2) image-processing MFD1, reduces noises due to dithering through hybrid processing of pattern- and error-diffusion dithering, thereby enhancing printing quality.

(1) MFD1 is available for Version 4.0 and higher. (2) Patent number: 5230816.

WAVEFORM CONTROL

Each ink colour has its own specific gravity and viscosity. To achieve a precise placement of ink droplets onto the media, Mimaki has designed an optimum waveform control technique that allows the printhead to jet each ink colour at an optimum angle, maintaining excellent ink droplet circularity. In each printing mode, ink droplet sizes from 7pl to 36pl are automatically selected to obtain optimum print results.

VERSATILE LUS-120 UV INK

Mimaki develops optimal UV curing ink for signage printing with the SIJ-320UV. The high-performance UV curing LUS-120 ink exhibits durability as well as flexibility. It provides beautiful, durable printing results even on soft media such as banner materials that are not laminated. ‘The UV LED ink platform has been accepted worldwide to be the best Eco-solution on the market,’ said Franco.

NCU AUTOMATICALLY DETECTS AND RECOVERS CLOGGED NOZZLES

Clogged nozzles are detected automatically by monitoring ink droplets with sensors. When clogged nozzles are located, these are automatically cleaned, reducing waste printing. Nozzles are checked per transfer file.

PRECISE MEDIA FEEDING MECHANISM SUPPORTS FINE PRINTING

Thirty-eight pinch rollers at equal distances and newly designed tension bars are installed to prevent media lift ing and to enhance feeding precision by applying equal pressure to the media at all points.

EFFICIENT AND VERSATILE TWIN-ROLL SIMULTANEOUS PRINTING

Taking advantage of the 3,200mm printing width, two media rolls can be mounted for simultaneous printing. Different print jobs (or the same print job) can be printed on two separate rolls. The user can select the preferred width separately for each roll, within a specified range (210 to 1,524mm).

WAVEFORM CONTROL TECHNOLOGY

Ensures high quality print resolution, by jetting ink drops in straight lines with almost perfect round dots, delivering clear and sharp letters, lines and edges.

SUPERIOR INKJET TECHNOLOGY

Delivers high density print by removing the gap between dots.

This article appears in the latest issue of Practical Sign & Digital Graphics magazine.