Ricoh Company, Ltd.’s Customer Experience Centre (CEC) dedicated to additive manufacturing, will be established as a place for co-creation activities. Ricoh will expand its CEC in Telford, the UK, on November 7 to accelerate co-creation with customers and partners in the manufacturing industry.

It will particularly benefit those considering using metal binder jetting 3D printers for electric vehicles (EVs), electric aircraft, etc., to create new value such as improving the energy efficiency of electric components (e.g. motors and batteries).

Through demonstrations, Ricoh will help customers understand the capabilities of Ricoh’s technology. Furthermore, Ricoh will also deepen its understanding of customers’ potential pain points through activities at CEC and propose solutions that can contribute to realising new value beyond customers’ expectations by providing 3D printers and a total solution for production workflow.

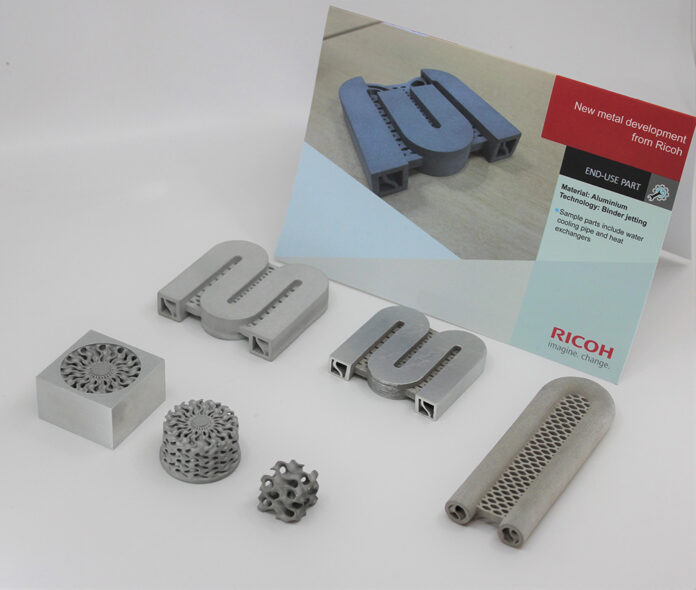

Ricoh has the technology to manufacture aluminium parts using a highly productive binder jetting 3D printer. Ricoh can use the strength of 3D printers to manufacture aluminium parts with complex shapes that cannot be made using existing manufacturing methods, producing lightweight parts, high-performance heat exchange parts, and other components. This will help solve the problem of cooling, which has become a significant issue in the electrification of various areas. In addition to heat exchangers, 3D printers have many other possibilities.

Ricoh has positioned the ‘realisation of a zero-carbon society’ as one of its material issues. Ricoh aims to achieve zero GHG emissions throughout its entire value chain, enabling customers to develop highly energy-efficient products by using Ricoh’s 3D printers, thereby contributing to the realisation of a zero-carbon society.

Tokutaro Fukushima, General Manager of Additive Manufacturing Business Centre, Ricoh Futures BU, Ricoh Company, Ltd., said, ‘There are technical issues with many products where they cannot fully perform due to heat problems or limitation of weight reduction. We are confident that Ricoh’s unique aluminium binder jetting technology will significantly contribute to solving these issues our customers face. With the opening of the CEC, we would like to accelerate co-creation with our customers to realise additional value for customers’ clients.’

‘Furthermore, we would like to actively promote collaboration with technical partners who have unique technologies. We hope to welcome partners who support our vision to ‘Make a significant contribution to a zero-carbon society and lead to the realisation of a wonderful future for children’ through co-creation activities.’

RICOH

https://www.ricoh.com