Embracing sustainability is yet another way Midcomp are constantly striving to be the ‘Catalyst for Growth’ for all stakeholders and their community. Midcomp, which are celebrating 30 years of sustainability and innovation, are the largest supplier of printers for the signage and point of sale industries that have the necessary environmental credentials to be used in the most sensitive applications. These printers include HP Latex solutions.

As part of one of the most sustainable companies in the world, HP Latex continues to lead the change in sustainable signage printing. Backed by the environmental and health certifications that matter most, HP Latex technology uses water-based inks. This innovation is not only a better approach for the environment, it empowers users to become more sustainable as well.

Water-based HP Latex inks offer an attractive environmental and health profile to both Print Service Providers (PSP’s) and their customers. With credentials addressing indoor air quality concerns, HP Latex inks produce odourless prints that can be used for indoor signage and décor, such as home, restaurants, retail or even hospitals.

HP’s newest Latex technology makes it the only large format digital printing manufacturer to earn ECOLOGO® Certification. This is issued by a third party (UL Environment) and recognised worldwide. The standard criteria include testing for heavy metals content and solvents, low VOC content levels as well as packaging recyclability.

Other HP environmental certifications:

• UL GREENGUARD GOLD 2: HP Latex prints certified. Certifies leading indoor air quality performance for demanding applications.

• AgBB (Germany) HP Latex prints on HP PVC-free wallpaper are AgBB certified for health-related evaluation of VOC emissions of indoor building products.

• A+ (France): HP Latex prints on PVC-free wallpaper are rated A+ according to Émissions dans l’air intérieur. Mandatory labelling for decoration products in France.

Midcomp: A Sustainable Company

‘Midcomp takes sustainability in all of its guises very seriously,’ said Midcomp Group CEO Rob Makinson. ‘We promote sustainable printing across our three businesses – in excess of 90% of our printer sales revenues are derived from printers using water-based inks. Sustainability is more than just the environment, it’s about our staff, our customers, their operators and ultimately end users. Healthier and low emittng prints are important for the environment and the global community.’

According to the Greenguard Certifications, HP Latex is the only ink technology that can be used to decorate 100% of the wall space in a hospital, nursery or school. ‘Everyone pays lip service to Greenguard Certification, but if you dig deep enough, not all levels of Greenguard Certification are the same. UV ink, solvent or eco solvent ink cannot be used to decorate 100% of the wall space in such sensitive environments. Of course, most South African PSP’s take advantage of the ignorance associated with harmful chemicals used in printing ink, but when the local authorities pick up on this loophole, we can expect Greenguard type certifications to be insisted upon,’ said Makinson.

Midcomp Azero is the leading South African supplier to provide Managed Print Services solutions to mining houses. HP Pagewide XL printers have become the de facto standard at all big mining houses. These printers, alongside the extensive HP Designjet range, also use water-based ink.

Sustainability Trends In South Africa

‘South Africa has to follow world trends and there is huge world-wide focus on environmental sustainability. As one of the first countries in the world to ban smoking in public places, South African authorities have proven quick to act against harmful exposure of its citizens,’ added Makinson. ‘The question is how soon the spotlight will fall on the printing industry as a whole, and the harmful chemicals used daily in the analogue and digital printing industries. With the post-Covid 19 tough economic climate combined with increasing environmental legislation pressurising companies to reduce material waste going to landfill, there has been a significant increase in the number of companies wanting to operate more efficiently. End users are also fast becoming very conscientious about their individual footprint and that seems to drive certain sustainability behaviour.’

Interior décor and interior signage in general have been the initial adopters of the green message. Wall covering applications are at the forefront of discussions to be environmentally and health conscious. Installing wall coverings (wall paper and the like) in sensitive areas like hospitals, schools, crèches, food displays and stalls has become a hot topic. ‘We are frequently asked by our customers about the environmental sustainability of not only the ink but also the printed media. There is an increasing demand for clever materials nesting algorithms like those offered by some of our flagship brands, like Zünd and Caldera. Our clients can save up to an average of 35% on material waste and also achieve a significant reduction in time to process, which equals less energy required,’ he said.

‘Once the ad agency fraternity and the corporate world pick up on these worldwide sustainability trends and start driving the industry to conform to the necessary steps to safeguard people who become exposed to the harmful nature of some of the ink technologies, the goalposts will move. It is not a question of if, it is a question of when,’ he added.

Recycling Programme

Midcomp are part of the free HP Planet partner recycling programme and have bins at their Innovation Hub that are delivered and collected free of charge by HP. Midcomp’s HP customers can enrol for free in the programme as well and HP will directly deliver a special HP recycling bin to, and collect the bin from, their printshop. They can conveniently put all of their used HP printheads, HP ink cartridges and laser toner cartridges into the bin. Watch the video here.

Creating Sustainability In The Industry

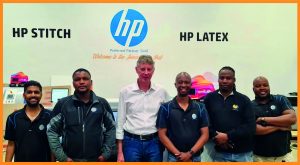

Midcomp train unemployed South Africans free of charge at their Innovation Hub to become digital print and finishing system operators. At the end of that training, Midcomp seek to find gainful employment in their customer base. The Innovation Hub is fully equipped with the latest digital printing and finishing equipment and acts as a backup production facility for customers on their Pay Per Use (PPU) programme, ensuring maximum uptime and meeting deadlines.

‘Midcomp’s vision for the future is that companies which consume digital print for any advertising space begin to consider the environmental sustainability and make their procurement decisions based on which PSP’s are able to conform to this new emerging trend,’ concluded Makinson.

Sustainability In Action: Baragwanath Children’s Burns Unit Project

The Baragwanath Children’s Burns unit approached Midcomp to help them make the unit a less scary place for the children who have suffered the traumatic experience of being severely burned. The idea was to install wallpaper in both the wards and the theatre where the burn survivors have their clothing removed and the burns treated.

The Midcomp Innovation Hub is equipped with HP latex printers, which are an ideal fit for the sensitive nature of branding in a medical environment because they use water-based latex ink with highest level of Greenguard Certification: Gold. Midcomp also used HP PVC-free wallpaper in the hospital wards. The installer only required a spray bottle with water and a squeegee to apply the wallpaper. He simply sprayed the back of the wall paper to activate the water based glue, similar to that of licking a postage stamp, and then applied it to the wall.

The Theatres are cleaned with a chlorine-based chemical, so Midcomp used a Drytac peel and stick smooth wallpaper over laminated with the Drytac Wipeout clear vinyl. This is an ongoing project as Midcomp believe that improving the environment helps in the healing process. For more information visit www.facebook.com/baraburnsunit/.

|

LOCAL DISTRIBUTOR |