Software manufacturer OneVision will showcase the latest innovations of its modular automation solutions across a wide range of print segments. A live showcase highlight will include a smart finishing process together with partner Kongsberg Precision Cutting Systems.

The impact of automation in the printing industry can be transformational and has a massive impact on the all-important bottom line. With challenges such as labour shortages and increasingly high material and logistics costs, workflow automation is becoming more than ever a crucial key to success for print service providers to ensure sustainable business.

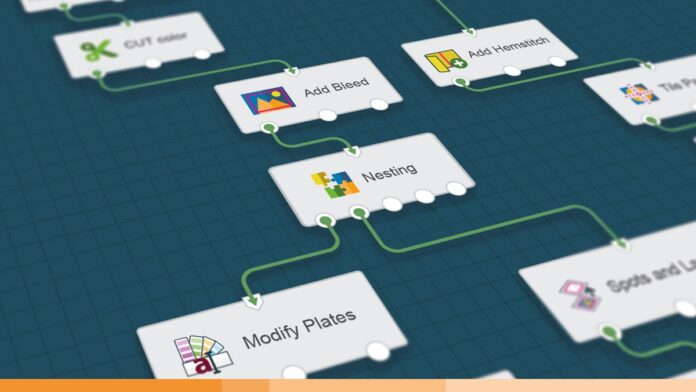

As so called middleware, OneVision’s automation software meets the approach of a seamless connection between order entry, file preparation, print and finishing. The basis of the software is an extremely flexible, easy-to-use workflow management system that can be connected easily to any other parts of the system landscape. Through the seamless integration, incoming files pass automatically through classic file preparation steps. According to the specific requirements of the respective print segments (e.g. book, commercial, label, wide format printing) files get then optimally prepared for embellishment and finishing. Intelligent tools such as nesting/ganging, tiling and paneling, cut line management, bleed creation, impositioning, and much more ensure a substrate-saving and efficient downstream processing.

Attendees at this year’s Printing United Expo 2022 can also look forward to a live showcase besides software demos performed by OneVision workflow experts. In cooperation with Kongsberg Precision Cutting Systems, the benefits of automated digital finishing of various substrates will be demonstrated. A Kongsberg X24 cutting system will be installed in the booth.

|

LOCAL DISTRIBUTOR |