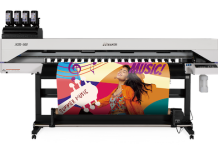

The new Colorado M-series is a modular 1.6m roll-to-roll printer with two speed configurations that also features Canon UVgel white ink, boosting the printer’s unmatched productivity and substantially expanding the range of applications that customers can create. This new series is available from Midcomp. This article appears in Sign Africa Journal.

Retaining Colorado’s industrial build quality, the new M-series design is based on a single platform that can be configured to customers’ needs and grow with their business, with easy in-field upgrades. The scalable series includes two base models (M3 and M5) offering a choice of output speeds – cruising speed of 29sqm/hr (312 square feet/hr) and 40sqm/hr (427 square feet/hr) and a maximum print speed of 111sqm/hr (1195 square feet/hr) and 159sqm/hr (1709 square feet/hr) respectively – with the option to upgrade from one model to the other. Both printers can be easily upgraded to ‘W’ versions for white ink (M3W and M5W).

UVgel ink

The introduction of a white UVgel ink maximises the scope for customers to benefit from UVgel’s renowned performance advantages for a full spectrum of premium graphics and décor applications – for example window graphics, labels and wallpaper. With this addition, and with new media detection sensor technology for easy media handling, Colorado M-series customers can expand their typical product offering using heavy structured, transparent, coloured, reflective and magnetic materials.

The unique gel formula on of Canon UVgel ink translates to fast build-up of dense and opaque white images in fewer passes than with conventional printing technologies, and printed output maintains its original whiteness over time. UVgel’s particular properties also eliminate many of the production, nozzle-cleaning and maintenance issues commonly associated with white ink, offering smooth, error-free printing, minimising ink usage and waste, and maximising productivity.

Customers can also choose the popular FLX nish+ option with their Colorado M-series printer, allowing them to add matt, gloss or mixed matt and gloss on the same print, without additional varnish. High-volume customers can automate the print-to-finish process with a UVgel Print Factory or UVgel Wallpaper Factory configuration, which seamlessly integrates the Colorado M-series printer with cutting, rewinding, taping or sheet stacking to manage volumes of at least 50,000sqm (500,000 square feet) per year with minimal operator time.

Peter Wolff, Chief Marketing Officer and Senior Vice President Canon Production Printing said: ‘Ever since they burst onto the market, Colorado printers with UVgel ink have set the highest bar for speed, quality and all-round productivity. On top of these business-critical performance criteria, customers today want to make smart, environmentally-responsible investments in large format graphics printing solutions that can evolve with them and help them tap into lucrative creative applications, products and markets. With the addition of an easy-care white ink option, the new modular Colorado M-series is the growth engine that businesses need to level up their capabilities and turn ideas into reality.’

Canon UVgel ink delivers pin-sharp image quality and consistent colour, while its instant drying properties enable immediate cutting and finishing, and its ultra- durability removes the need for lamination. Like previous Colorado models, the M-series is designed to handle the workload of multiple legacy roll-to-roll printers, with industrial-grade round-the-clock reliability and unattended printing with minimal operator intervention. The new M-series Colorado printers are supported by PRISMAguide XL, the easy and powerful make-ready so ware which results in effortless production runs with consistently high quality.

Compared to other ink technologies such as latex or eco-solvent inks, UVgel technology consumes up to 40% less ink to build up the same image quality and colour intensity. The low-heat, energy-efficient LED curing system and ‘instant- on’ opera on results in reduced energy use compared to other technologies. Furthermore, with UVgel technology, customers can print on environmentally responsible materials such as PVC-free and paper-based media, even uncoated. This means the Colorado M-series printer fits perfectly in a sustainability- conscious organisation.

The Colorado M-series is designed with low total cost of ownership and rapid return on investment in mind, thanks to the lowest operating costs in its category, the ability to produce high-value applications, and the unique modular upgrade options.

Suitable for a wide range of print and signage businesses

The Colorado M-Series is aimed at print service providers (PSPs), such as sign makers, who already have large format print businesses, or those who see an opportunity for large format, roll-to-roll applications. With the Colorado M-series, they can expand their in-house graphic arts production capabilities, increase their efficiency or explore new business. Because the Colorado M-series can be upgraded in the field, it can scale up with them as their business grows. The Colorado M-series offers an extended application range through its breakthrough white ink and even more versatile media range (structured, black backed, reflective, transparent and coloured media).

The printer is also ideal for producers of wallpaper, packaging, and other specialised high-volume items. Print companies like these are dedicated to specific applications that are produced in very high volumes. The cost efficiency and productivity of the Colorado M-series are important factors in the purchasing decision, along with the unique high quality that UVgel brings in terms of print robustness, colour consistency and dimensional stability of the printed products.

With the M-series, Canon are offering an extended application range because of the white ink and broader specialty media range that can be handled. For very high volume users, they are offering the UVgel Print Factory that allows reliable handling of jumbo rolls.

Mass customisation is here to stay and typically leads to the production of larger batches of similar products, where each product is tailored to the end-user’s needs. This type of production, enabled by digital printing, is often done at large scale in central print factories, which could even be part of larger corporations with multiple regional production locations. Print factories can easily produce volumes of more than 1,000,000sqm per year. With the white ink option and expanded media range capabilities of the M-series, these print factories can now produce applications, such as window graphics, much more efficiently than with their existing equipment.

Sustainability advantages

• Compared to other ink technologies such as latex or eco-solvent inks, UVgel technology consumes up to 40% less ink to build up the same image quality and colour intensity.

• Significant reduction of media waste because of printing on the leading edge.

• The low-heat, energy-efficient LED curing system and instant-on operation results in reduced energy use compared to competing technologies.

• Furthermore, with UVgel technology, users can print on environmentally friendly materials such as PVC-free and paper-based media, even uncoated. This means the Colorado M-series printer fits in a sustainability-conscious organisation.

• Safe working environment: the Colorado M-series comes equipped with internal filters and can be installed and operated without dedicated exhaust extraction installed on or near the machines.

• The amount of volatile organic compounds that the UVgel technology emits is negligible.

• In addition, it is designed to be below thresholds for UV, visible and IR radiation and noise emission while in use, according to ACGIH institute standards and ISO7779/EN27779.

• The new Colorado Sustainability Calculator gives customers insight in to their sustainable performance by calculating and comparing their footprint during the usage-phase in terms of energy consumption, ink usage and carbon emission.

The Colorado M-series printers can be refurbished for new customers or its components and materials re-used via Canon’s asset recovery plant. Canon are signatories to the UN Global compact, committed to responsibly meeting their customers’ sustainability needs and thus acting as a responsible corporate citizen. Canon is also a partner of WIPO GREEN, an international programme that promotes the coordination of technologies for environmental protection.

Field upgradable

Options and upgrades can be simply carried out at the customer’s premises or even remotely. Adding the white ink op on can simply be done with a short service visit, while the magnetic media kit and jumbo-roll interface just involve easy in-field upgrades. Other additional functionality, such as a speed upgrade, is licenced and can be remotely activated, which is unique.

State of the art printheads

These printheads have a higher number of nozzles per printhead. The printheads are more productive than the previous generation, so fewer of them are needed. They also use ink more efficiently compared with the previous generation. They enable the speed licence upgrade and have been designed for additional channels, such as white.

New sensor technology

The new sensors, in combination with new markers, (for structured and white ink-based) extend the wide media range of the Colorado M-series even further. Challenging media, such as fully transparent, reflective, coloured or black back media, are now also supported. This enables products such as window graphics, structured and shiny wallpaper, fleet graphics, transparent decals, magnetic applications for example in retail environments, multi-layer applications (like 5-layer), pre-coloured media types, and block-out films with black backings.

Series improvements

The M-series can handle many more media types than its predecessors. However, the main improvement is in Canon’s improved maintenance concept, which further reduces manual operator maintenance time and ink consumption, while increasing print quality.

To keep these nozzles in optimal condition, reduce manual maintenance by operators and minimise ink purging for maintenance, the Colorado M-series features a whole new automatic maintenance concept: an easy-to-use tissue cassette which automatically cleans the nozzles, based on real-time nozzle status information.

See the machine in action

Midcomp will host a two day open house on the 13th and 14th June at their Innovation Hub in Ferndale, Randburg. Limited seats are available, and bookings are essential. RSVP: sales@ midcomp.co.za

|

LOCAL DISTRIBUTOR |