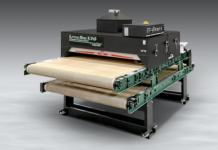

The eight and a half metre long UV and Airforce Twin Belt Dryer was manufactured at Natgraph’s Nottingham based factory and allows the operator to independently control belt speeds on the two dryer belts, enabling a great level of flexibility for curing and/or drying two different products at the same time.

Natgraph’s highly skilled engineers manufactured the Twin Belt UV Dryer with independent speed control for the two separate conveyor belts after a customer contacted them with the specific request.

The Twin Belt Dryer also benefits from a positively tracked belt, which ensures that the belt will stay within 2mm tracking tolerance, perfect for production processes requiring an added element of precision.

Space restrictions on the two independently running belts were the main considerations for the design and manufacturing team, which completed the project in a short time frame to suit the customer.

‘Our in-house design and manufacturing capabilities allowed us to meet our specific customer requirements enabling the customer to maximise flexibility in their demanding production requirements,’ said Darren Kerry, Head of Technical at Natgraph Ltd.

NATGRAPH

https://www.natgraph.co.uk