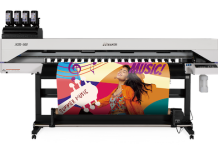

Mimaki will launch the MM700-1800B, a high-speed 1.8m-wide roll-to-roll direct-to-textile inkjet printer, in May.

Tastes and preferences in the textile and apparel markets are becoming more diverse. In recent years, there is a continuing shift away from traditional analogue printing methods of mass production to digital printing that allows on-demand production with a wide range of personalisation and adaptability to individual needs. Accelerating the trend further is the arrival of ‘extreme on-demand production’, in which orders are accepted via the internet for mass production of freely customisable ‘one-of-a-kind in the world’ items.

Mimaki predicts consumers will begin to regularly create custom designs once they have grown weary of ordinary design options in the marketplace. To accommodate such ultimate order-made printing, the company will offer solutions to realise diverse printing with digital on-demand printing.

The MM700-1800B uses various sensors and cameras during printing to automatically detect the textile feed advancement distance, seams, media jams due to head striking, meandering and more, as it controls the transport of the textile. The printer itself makes adjustments to prevent trouble before it occurs, according to Mimaki, allowing stable printing to continue without constant operator supervision.

Its carriage is driven by a linear motor that gives it positional accuracy on the micron level, which combines with a ‘variable dot’ system, delivering ink in multiple drop sizes to produce beautiful prints with even higher accuracy. In addition, its 16 printheads arranged in four staggered lines achieve a best-in-class print speed of 800sqm/h.