The Artista Textile Colour Collection and Mimaki Profile Master 3 (MPM3) for advanced printer profiling are designed to help printers deliver accurate, repeatable colour across multiple devices and locations.

In the textile industry, the shift from analogue to digital production is underway as textile and apparel manufacturers aim to achieve faster time-to-market, reducing inventories and increasing flexibility to address rapidly evolving trends. Yet colour matching remains a significant issue due to the lack of a standardised colour charts that enables colour consistency from design through production. Mimaki is filling that gap with the Artista Textile Color Collection, making it faster and easier for textile and apparel manufacturers to achieve the desired colour without wasteful trial and error.

‘This collection will be expanded over time,’ said Mike Horsten, General Manager Marketing EMEA for Mimaki, ‘but in its initial form, it includes 520 colours for sublimation transfer printing, including eye-catching fluorescents, which are ideal for sports apparel and interior fabrics. The process is integrated into the workflow beginning with design and enables the production of consistent colour, even across multiple locations.’

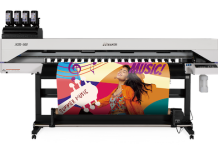

The process starts with a designer specifying colours based on new swatches made available for Adobe Illustrator or CorelDRAW. An image file based on the selected colour palette is then printed on a Mimaki printer using either the RasterLink6 or TxLink3 RIP software. In addition to colour-accurate images, the resulting standard includes detailed information about profiles and settings that can be used to reduce the time required for colour matching. Thus enabling colours to be represented accurately across printers and locations. The initial collection is designed for use with the Mimaki TS300P-1800 textile printer with dye sublimation inks.

Media affects colour appearance, making it difficult to match colour across different media types and using different printers. Mimaki is simplifying this process with the new Profile Master 3 (MPM3) colour management software. It enables users to reproduce equivalent colours when printing on different types of media with the same printer or when printing with different printer models and inks, vastly increasing the flexibility of a production platform, even when it consists of printers from multiple vendors.

It’s easy to use, requiring no special colour knowledge and speeds the integration of new printers into the mix, ensuring excellent colour matching across the entire platform. This makes it easier to split up larger jobs across multiple printers or produce projects that include pieces printed on a variety of printers, reducing cycle time and increasing quality and consistency. Print colour is consistently maintained over time by measuring colour with a colorimeter during the printer calibration process.

‘We are excited about these developments,’ Horsten concluded. ‘As always, our objective is to bring market solutions that not only make production easier for our customers but improve profitability as well.’