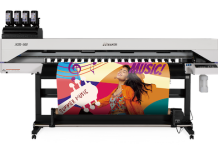

Mimaki Engineering Co., Ltd. has introduced the revolutionary new high-speed UV LED flatbed wide format printer, the JFX500-2131. The printer achieves a maximum speed of 60sqm/h (2.5 times faster than that of conventional JFX plus series) and is ideal for the sign and graphics industry and wide format display marketplace.

The JFX500-2131 sets a milestone in design and performance from Mimaki, offering a newly developed print head, UV ink and advanced UV LED curing features.

Mimaki offers a precise head movement control feature that produces exceptional high resolution image quality. The printer is equipped with white ink circulation and ink degassing module that enhance operation stability.

The printers’ operations and command functions are easy to understand and it uses long-lasting LEDs, resulting in less power consumption and reduces waste by offering a refillable 2 litre ink system vs. disposable cartridges.

Equipped with the new developed print head (six print heads with three staggered configuration), the JFX500-2131 achieves print speeds of up to 45sqm/h for white ink printing applications.

LUS-150 (*2) is a newly formulated CMYK LED curing ink with high speed curing properties. This ink offers improved curing times resulting in a less tactile sticky feeling and it is flexible up to 150% (*3). This results in increased elasticity and bending performance on a wide variety of media and substrates without cracking or fracturing the cured ink during handling, cutting or other post-print processing. The JFX500-2131 also operates with LH-100 CMYK inks, a more rigid ink formulation for printing on hard surfaces requiring greater adhesion properties. In addition, the JFX500-2131 can utilise Mimaki’s LF-140 flexible ink available in six colours. All ink formulations also offer white ink.

Mimaki’s new UV LED unit is optimized for curing efficiency, leaving no uncured ink. With LED UV curing, the printer delivers high speed UV printing with all of the advantages of LED technology, including long-life, energy savings, lower heat generation, the ability to use thinner, more cost-effective media and printing on heat-sensitive media that cannot be utilised with conventional UV curing systems.

This printer includes two units of Mimaki’s unique and highly-accurate linear scales controlled by an Intelligent Microstepping System (IMS) fine step accuracy and dot placement. This results in far less banding artifacts and the ability to print legible 2 point characters on most media. Variable drop functionality produces three different drop sizes simultaneously. The minimum drop size is an amazing 4 pico-litres that produces a smooth, natural gradation without granular appearance even in 4-colour mode. Mimaki’s proprietary head control technology delivers unrivalled high definition and high resolution prints.

The Mimaki Advanced Pass System (MAPS) effectively reduces bandings with multiple printing passes, using a gradational mask pattern. When this option is selected, UV curing is performed more gradually which diminishes any appearance of banding.

Mimaki Circulation Technology (MCT) ensures ultra-high performance in white ink printing. This standard option regularly circulates white ink, enabling stable output from machine startup by eliminating settling of white pigment in the ink lines. Additionally, MCT contributes to reduction of ink waste, thereby supporting environmentally and economically friendly applications. In addition, the Mimaki Degassing Module (MDM) eliminates the gasses or bubbles inside the ink reducing nozzle blockage and improving accuracy of ink dot placement. This module enables the printer to use undegassed bottled inks instead of conventional degassed ink packs, thereby reducing ink costs.

The Mimaki JFX500-2131 is equipped with pins and a scale that eliminates annoying alignment procedures generally required in flatbed printing. Simply fix the substrate to layout pins, check placement with the scale, and edit the design data or printer settings accordingly, resulting in direct UV printing without misalignment.

RasterLink6 features intuitive operation. Print and other conditions can easily be set with related settings consolidated into a single window. In addition, stored layouts can be reused at any time by using the ‘Register as Favourite’ designation. Its colour replacement function enhances the ability to re-create printed images. Selected colours from the RasterLink 6 colour charts can easily be added into Adobe Illustrator swatches. Users can also simulate printing colours in Illustrator or Photoshop prior to actually printing, saving both time and money in the design and production process. Additionally, the RasterLink 6 RIP simplifies reverse printing. Simply select the order of over- and under-print with white in RasterLink6, and the most efficient path is automatically determined without further operator intervention.

UV curing printing is an ecological printing method that minimizes VOCs. The curing efficiency of the newly developed UV LED unit has been improved compared to that of the conventional one. It is powerful and reduces power consumption while offering much longer life cycles and increased operability. Every UV ink is supplied in 2L bottles. This ecological and economical ink package contributes to reduce amount of industrial waste and running cost.

Select the order of over- and under-print with white in RasterLink6, the bundled standard software RIP. The most efficient path is then determined by the software. Operators experience efficient high productivity gains without further operator intervention.

Even if nozzle washing has no effect on a troubled nozzle, the print image quality can be retained temporarily. During this nozzle downtime the printer continues to produce high quality prints until the Mimaki service team arrives.*Nozzle Recovery Function is a temporary failure averting function and its recoverability is limited.

3-layer print of colour, white and color can be performed at the same time. The underlay printing of a base layer of white ink reproduces the natural beauty of process colours printed on transparent substrates with high precision and no multi-pass color registration shift.

It is equipped with imprinting function which supports variable data. Using a list created by Microsoft Excel, etc., you can imprint variable data such as addresses and names.

When a print job is completed, or ink is running out, or an error condition occurs, you will be notified by an e-mail sent to your e-mail address registered in advance. The events such as ‘Printing will be finished in five minutes’ or ‘The ink is running out’ will be your notification to avoid the stop of printing operation.

Supports the Web update function that has been well-received in RasterLinkPro5. Programme updates and profile downloads can be easily performed via the internet.

*2 LUS = LED UV Stretchable ink

*3 Ink flexibility of LUS-150 and LF-140 may vary according to the substrate, please verify your substrate in advance.