Mimaki has announced that its production-class Tiger 1800B digital textile printer family has been enhanced with new features and capabilities as the company continues to drive higher quality in digital textile printing.

The Tiger 1800B MkII, which debuted at FESPA 2018, offers an additional high-quality mode at 1200dpi and several enhancements to improve quality, including reduction of banding and other printing defects.

‘The conventional-to-digital transformation continues to heat up in textiles and apparel, and Mimaki, an early mover in this space, is dedicated to bringing affordable, industry-leading solutions to this segment,’ said Bert Benckhuysen, product manager EMEA at Mimaki Europe.

‘The Tiger 1800B MkII printers, available in two models for direct to textile and heat transfer sublimation, are just another example of this strategy in action. And our strategy goes beyond simply providing outstanding printers – especially in an emerging market such as this, it is critical to be a Total Solutions Provider. To that end, we are also making available a new range of pre-treatment and post-treatment machines, and we are working towards the development of Internet of Things for the Textiles and Apparel market.’

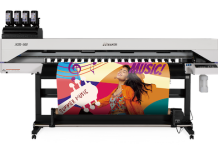

The Mimaki Tiger-1800B MkII prints at up to 385 square metres per hour and can cover a wide production range, from sample making to small to medium print runs. An additional 1200 dpi print mode is available for enhanced print quality.

A set of Mimaki’s unique Core Technologies has also been added to the machine. Mimaki Advanced Pass System (MAPS) minimises banding and colour shifting by spreading the edge of the pass, making the boundary area a gradation, resulting in a smoother printed image. Mimaki’s proven Nozzle Checking Unit (NCU) and Nozzle Recovery System (NRS) are also incorporated in these new printers, enabling continuous high quality printing even if nozzle errors occur.

Mimaki is also making available an extensive line-up of optional devices to meet just about every fabric and transfer paper printing need. This includes a feeding unit for roll media equipped with a centering device and tension bar; a jumbo roll unit to enable printing of long-length roll fabric or heat transfer paper; and drying and winding or pleating options for printed fabrics.

The Rimslow Series

The Rimslow Series is a complete, end-to-end digital textile and apparel printing ecosystem.

It was demonstrated at FESPA 2018.

‘Currently, businesses wishing to participate in the digital textile printing revolution must purchase printers and pre- and post-treatment solutions from different manufacturers,’ said van den Broek. ‘Not only is this inconvenient, but there can be implementation issues with no single source of responsibility to resolve them. Following our acquisition of Australian company Rimslow last year, Mimaki now has all the necessary components in place, including pre-treatment of fabrics, digital printing, and steaming and washing post-print with the Rimslow Series.’

Mimaki also announced its first development in the Internet of Things (IoT) for Textiles and Apparel (TA), adding another layer to speed processing and to reduce errors. Named Mimaki Job Controller TA, the new development includes functions to provide production condition management, barcode scanning, and visibility into the production database. Together with Mimaki’s range of textile machines, these components comprise a complete digital textile printing ecosystem that makes entry into digital textile printing a virtually risk-free venture.

Printing textiles with digital inkjet technologies typically requires four discrete steps:

- Pre-treatment of fabrics prior to printing is required to ensure optimum interaction between the ink and the fabric and to prevent ink bleeding. By using the Mimaki TR300-1850C Pre-Treatment Unit, businesses can bring the pre-treatment in-house, reducing costs, shortening production cycles, and gaining increased control over the entire process.

- Direct inkjet printing of textiles is accomplished using a Mimaki textile printer such as the new Tiger 1800B MkII production-class digital textile printer, which will be on display at FESPA.

- Steaming of the printed fabric is required to fix the ink on the fabric. This is accomplished with the Mimaki TR300-1850S or the Mimaki TR600-1850S Steamer.

- In the washing step, leftover ink and treatment agent are removed from the fabric, and making it ready for the next steps in manufacturing and/or distribution. The Mimaki TR600-1850W Washer is used during this step.

An important factor in controlling the quality of the finished product is the ability to control the production process and ensure consistency from one run to the next. With the new development in Mimaki IoT for the TA Market, this is accomplished with three important components:

Production Condition Management, designed to record production condition data and manage production conditions that can change depending on the type of textiles, inks and final products being produced. This data can be used to ensure consistency when repeating jobs and to simplify the ability to use multiple printing units in parallel to increase printing throughput and ensure efficient workload distribution.

Production Condition Barcodes can be used to call the production condition management data from the production database to set up a job automatically. This speeds job set-up, reduces human error, and makes it easier for even less experienced operators to deliver quality printed textiles.

Visibility into the production database provides management with relevant information, including actual production numbers, production staff involved in the process, production time and failure rates, in addition to production conditions. This provides management with real-time data for better decision-making and continuous improvement efforts, including cost/profit calculations and better production planning.

‘With the launch of the Mimaki Digital Textile and Apparel Ecosystem, and following our joint venture with Bompan in Italy, we are working towards the realisation of bringing a Total Solutions Approach to the digital production of textiles and apparel,’ van den Broek added.

Upcoming FESPA events include FESPA Africa, the region’s largest, focused exhibition for wide format digital printing, screen printing, garment decoration and textile printing, which is co-located with Sign Africa and Africa Print, the region’s leading events for the signage industry. The event is taking place from 12-14 September 2018 at Gallagher Convention Centre, Johannesburg.

Graphix Supply World (+27) (0) 21 511 5340 marketing@gsw.co.za www.gsw.co.za