Mimaki hosted a webinar titled ‘Industrial Market Edition’, which focused on the impact of Covid-19 on the digital printing industry and the industrial and manufacturing sector.

Panellists:

– Haydar Citgez, Sales Manager at 3A Composites GmbH.

– Alexander Jauker, Head of Strategic Marketing at Trotec Laser GmbH.

– Duncan Smith, Sales Director at Brett Martin Ltd.

Additionally Michelle Ferguson, Director at Scotland’s Bravest Manufacturing Company, and Maikel de Wit, Owner of Marketiger, were available for a customer discussion.

Impact on business – how did you adapt?

Smith emphasised on employee safety, and mentioned an increase in demand for sheets and screens for PPE, while Citgez spoke about how the company focused its efforts on developing webinar concepts and materials for PPE.

‘We shut down production temporarily and had to have virtual interactions with customers,’ said Jauker, ‘Customers were very creative in changing their business models during this time.’

How do you market your products?

‘We’ve been very active on social media,’ said Smith, ‘It was difficult to send photographers out, so we used customer photography. We shared creative ideas, put out special brochures and pamphlets, and advised customers on material selection for face visors. We are looking forward to when expos start again, not just for our customers but for our own products.’

Product popularity

Citgez said there was an increase in demand of masks, visors and counter displays, and encouraged creativity and versatility for staff and customers alike.

Jauker echoed that it had been pretty much the same, ‘In every crisis there is an opportunity. Our customers had an 800% increase in work with face masks, protective walls, etc.’

Key trends for the rest of year

‘Restaurants and businesses opening,’ said Smith, who emphasised the need for more plastic screens, ‘but we need to make screens more attractive -they can be made more aesthetically pleasing.’ He also mentioned the printing of names, brands, patterns and colours on screens, as well as messages that welcome customers and people back to work. Another trend he cited was a growth in antimicrobial products, i.e silver ion technology, which was previously just used in medical applications.

‘Hygienic products, extra signage and products for the hospitality sector are big with our customers’, said Jauker, ‘we also see opportunities in online personalisation’.

Helping customers overcome challenges

‘We try to provide customers with files for cutting face masks, templates, laser parameters etc,’ said Jauker.

Smith cited social media and video conferencing, as well as customer training sessions, while Citgez cited encouraging customers to go into new markets, using machinery in different ways, and helping customers to save costs in processing and supply.

Important lessons learned

‘It is interesting to see how your own company adapts in new situations,’ said Citgez, speaking about how his company had implemented new ways within hours or days, which normally takes much longer.

‘It’s amazing to see how everybody was so flexible and adjusted to a new situation so quickly,’ said Jauker, ‘Decisions were made in days and weeks, not years. Everybody was open to make things happen. It was amazing and fascinating to see our people adapt to a new situation.’

Following a tour through the Mimaki demo facility, with a focus on the company’s UV technology in action, two Mimaki customers shared their insights.

How did Covid-19 affect your business? How is it now?

‘We try keep people working,’ said de Wit, and mentioned how his company split up responsibilities during a time when many clients needed to shut down. ‘We took precautions for worker safety, and some business needed to be let go. Making things work to our advantage was our focus.’ This included rapid prototyping for medical applications, and advising various companies.

‘We had to adapt,’ said Ferguson, ‘We had a Mimaki printer donated to us, spoke to clients and offered them Covid-19 signage within a short time frame.’ Ferguson mentioned the machine’s ease of use and how it printed large volumes of signs quickly.

Adapting your business in Covid-19

De Wit, whose company is largely focused on 3D printing, spoke about shifting the business away from full-colour printing and moving towards Covid-19 products, such as door-handle openers (hygiene hooks).

New projects/opportunities

‘We needed screens for veterans’ family visitations for a care home, which involved manufacturing screens that were not clear (for privacy), but also branded,’ said Ferguson, who also spoke about an increased need in signage for hospitals, prisons and infrastructure, where the Mimaki machine really stepped up.

De Wit said that during this time a major trend that emerged was that online business went up, while (conversely) physical business went down, and said you need to be creative with the tools you have. ’The holidays affected sales, but as they are ending sales are coming back. People are slowly returning to work and want our PPE products.’

Ferguson said much the same as well as that, ‘Companies will have to continue thinking about Covid-19 messaging, because the pandemic is not going away any time soon.’

Trends

‘The Covid situation has showed people the complexity behind 3D printing, and with that its opportunities,’ said de Wit, while Ferguson spoke about getting products out quickly, as well as that the trends for signage will increase.

Advice

‘Be creative, accept Covid-19 is here and not going away any time soon, and be open-minded,’ said de Wit.

‘Put your people first – your team, customers and employees – do things fast, watch your markets and watch what is coming ahead,’ added Ferguson.

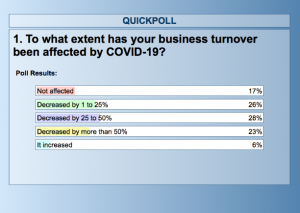

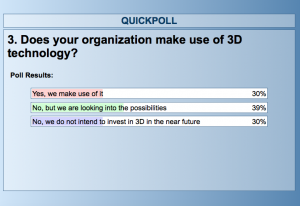

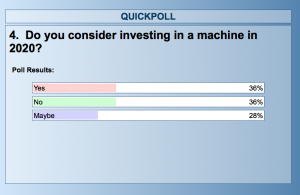

Polls that were conducted indicated the following:

|

LOCAL DISTRIBUTOR |