Midcomp’s new iDigit pattern digitising software allows users to digitise patterns of any size, colour or material, including: card, plastic, paper, textile, plywood, calico, leather, Mylar, metal and more. The software is also widely used for digitising vehicle livery and signage patterns, and more.

‘Digitising as a service is highly sought after and exists as an additional value added service all on its own. So sign makes can approach all of the markets listed above, and it may be a foot in the door for other services they can offer,’ said Midcomp’s product manager for iDigit, Sean Greer.

Apply iDigit for speed, accuracy and cost. Users no longer have to waste time with manual digitising and there is no more time-consuming laying out of patterns with the aid of adhesive tape, like with table digitisers.

Most photo digitisers require calibration, which is also time-consuming. iDigit offers users high productivity with calibration-free digitising technology. Simply digitise two-dimensional patterns from a picture and export into a CAM/CAD system for processing, plotting or cutting.

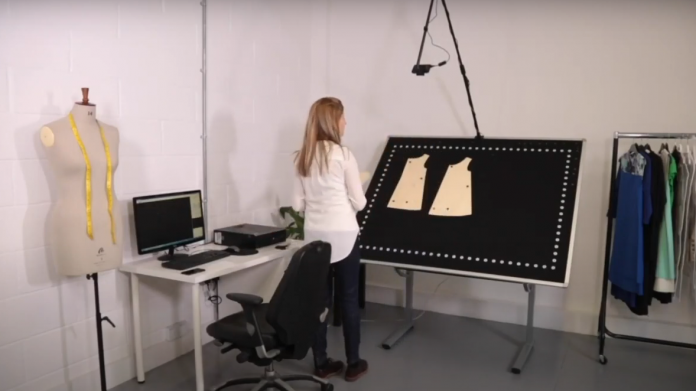

The iDigit magnetic board is either fixed on a wall or laid flat on a table for a compact solution that fits any workspace. Even if users take pictures of their patterns from a different angle each time, iDigit will always produce the same accurate results with intelligent correction algorithms.

Easy to learn and to operate, iDigit is compatible with all major CAD/CAM software. Smooth out rough-edged patterns automatically. Digitise cut-outs, notches, drill holes, internal lines and grain lines automatically while ignoring the positioning magnets. For the apparel industry, iDigit is equipped with sophisticated functions such as the automatic detection of features, the ability to digitise dark-coloured patterns as well as hard-to-digitise fabrics or worn-out paper patterns.

Ideal for use in a vast array of industries including furniture, clothing, sign manufacturing, marine, aerospace and composites industries. iDigit can easily digitise patterns made from any material such as paper, wood, leather, fabric, plastics and other manufacturing materials that need to be reverse engineered. In the automotive industry, iDigit has the ability to digitise highly intricate patterns for an accurate representation of the original template.

Templates made of actual composite materials may have rough edges and iDigit is equipped to smooth out such edges and to even correct worn paths. Even glossy composite templates are easily processed. For metal sheets, templates can be highly complex with intricate internal cut-outs, making these extremely time consuming to manually calibrate. All the detailed cut-outs and drills of metal sheets are accurately detected, within seconds, with iDigit.

‘The price point of a standard digitising system, which comprises of an electronic board with a matrix of wires running through it and a fancy mouse that you literally trace the product by hand with, is double the price of the iDigit system. Our customers asked us to find a solution that was cheap and hassle-free. It did not take us long to find iDigit due to the sheer volume of systems that have been installed globally for so many different applications. It just made sense to add this brand to our portfolio of high-quality printing and finishing solutions,’ added Greer.

Greer said Midcomp has had great feedback so far about the product. ‘Capturing patterns in 30 seconds from a photograph to a saved DXF file is saving our customers so much time. The return on investment speaks for itself in terms of investment versus man hours saved.’

|

LOCAL DISTRIBUTOR |