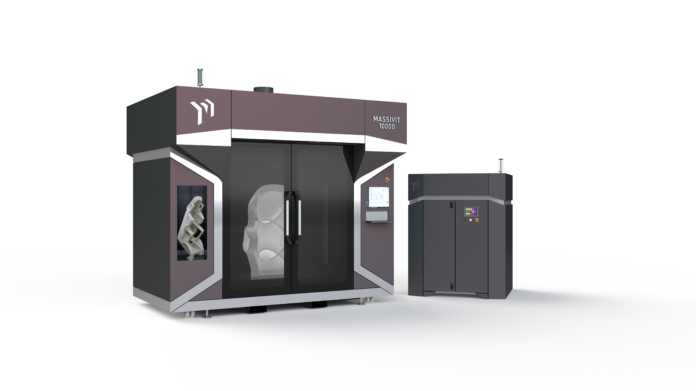

Massivit 3D Printing Technologies has announced the introduction of its Massivit 10000 composites tooling system.

The Massivit 10000 additive manufacturing system was conceived to overcome the recognised bottleneck associated with composites tooling by automating the process. It leverages thermoset polymer casting materials that provide a high Heat Deflection Temperature (HDT) and low Coefficient of Thermal Expansion (CTE).

Based on the company’s newly developed Cast-In-Motion (CIM) technology, it combines ultra-fast additive manufacturing with direct casting of proprietary, industrial-grade, dual-component, Epoxy-based material.

The new technology eradicates the need to produce an initial master (or plug). This consolidates existing 19-step moulding workflows into just four steps. In addition, the Cast-In-Motion technology also offers exceptional geometry freedom for complex designs.

Massivit 3D has already penetrated the global additive manufacturing arena with a portfolio of large-scale 3D printing systems installed by its customers across 40 countries. The company plans to expand into multiple FRP arenas with its new, disruptive technology – including the marine, automotive, railway, consumer goods, sporting goods, aerospace, and other industries. With a build volume of up to 1.2 x 1.5 x 1.65m (3.9 x 4.9 x 5.4 feet), the Massivit 10000 is suitable for a wide range of applications for those industries that are looking to dramatically shorten lead times compared to traditional production.

MASSIVIT 3D

https://massivit3d.com