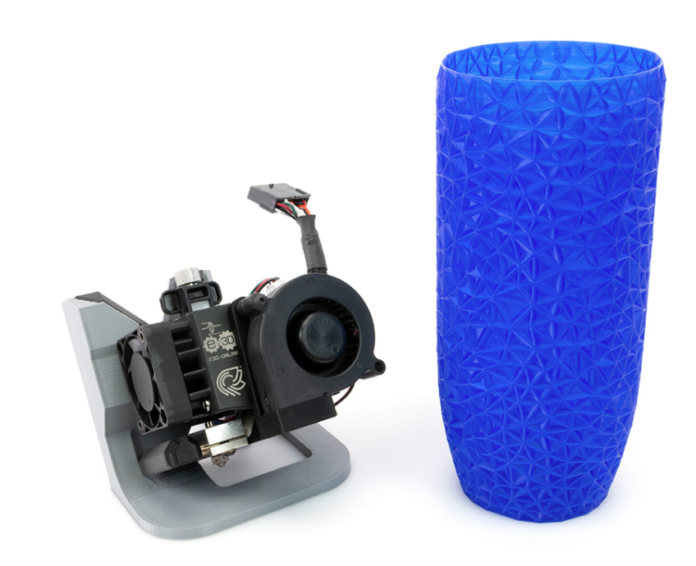

The new LulzBot H175 tool head features a dual-drive, hardened stainless steel drive train with a fully constrained short filament path combined with the reliable E3D V6 hot end. The E3D Hemera extruder on the H175 provides unrivalled precision by giving ideal control over stops and starts; considerably reduced stringing and blobbing and greater filament traction, which means slipping and grinding filament are a thing of the past.

Material changes are easy using the quick release lever. A conveniently accessible thumbscrew tensioner allows the user to fine-tune the pressure exerted by the drive gears onto the filament.

As with all of LulzBot’s new tool heads, the H175 has been designed with the Universal Mounting System, making it a drop in upgrade for the current line of LulzBot 3D printers. It also allows for rapid changes of Tool Heads – each designed for specific tasks and filament diameters within the LulzBot ecosystem.

The E3D Hemera heatsink on the H175 optimises airflow using die-cast fins. Airflow is directed up and away from both the hot end and the heated bed, meaning airflow does not disrupt the print envelope. This reduces the risk of warping and uneven stresses forming in the printed part. The sturdy fan duct has been designed for maximum efficiency using airflow analysis to ensure even 360° part cooling. The fan duct also provides a direct view of the printing surface, so users can inspect layer quality during printing.

LULZBOT

https://www.lulzbot.com/