Having implemented Kornit’s direct-to-fabric technology, Poland-based SE-DA’s incoming orders are produced with very little set-up time, the products are vivid and soft to the touch and the imprinted materials have a superior light and wash fastness necessary for long-term use. Requiring less inventory has helped improve SE-DA’s bottom line.

According to Kornit Digital, SE-DA has created a ‘microfactory’ production model using the Kornit Presto S system for eco-friendly direct-to-fabric production. Operating as a family business since 1990 and employing a staff of about 200 employees, SE-DA is a professional supplier of high-quality textiles for hotels, restaurants and healthcare facilities, in addition to home goods. They offer a wide range of decorative fabrics, including curtains, blinds, bedsheets, bathrobes, towels, slippers and bathroom rugs. SE-DA engages in e-commerce via their HotelTex website, and print and sew various pieces in a variety of materials and quantities on demand.

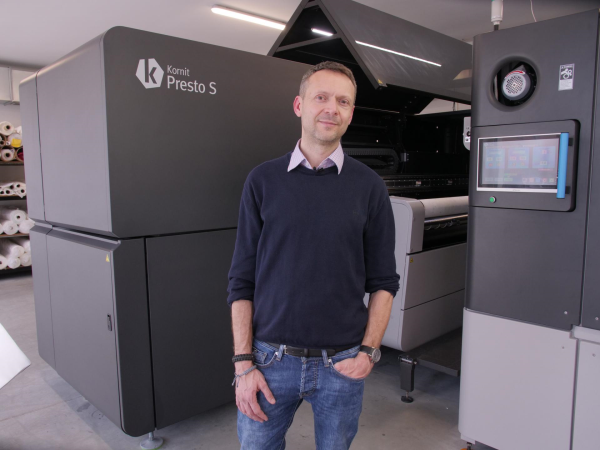

‘As the demands of our customers grew, we found Kornit Presto S was the best all-around product we could find for high-quality printing to many different fabrics, which gives us great flexibility,’ said Damian Marchlewicz, CEO at SE-DA. ‘The fact that pre and post-treatment is completely inline makes it possible to print very quickly, keeping costs low while ensuring the production process is environmentally-friendly as no water is used during the entire production process.’

While Kornit’s system represented a significant investment for the business, Marchlewicz noted Kornit technicians have been very supportive and helpful in ensuring their comfort with using and maintaining the technology, from the evaluation process to installation.

‘Having completed a few training sessions, we’ve found the Presto system very easy to operate, without dedicating a lot of time to learning how to use it,’ he said. ‘Multiple prints go into a single feed, which helps minimise our costs, and the customers get a very high-quality graphic that meets any standard in place. We see a great future in the print-on-demand business.’

Assisted by Kornit’s technology, SE-DA is currently in the process of becoming GOTS and GRS certified. ‘Kornit’s single-step, eco-friendly production technology offers considerable value to any textile company that needs to deliver high-quality pieces, in any quantity, in short order,’ said Chris Govier, KDEU Managing Director. ‘SE-DA produces materials that must be safe and durable, standing up to a great deal of wear and tear, and with this system they can guarantee any number of pieces that will exceed the demands of hospitality and healthcare, using responsible and sustainable methods.’

|

LOCAL DISTRIBUTOR |