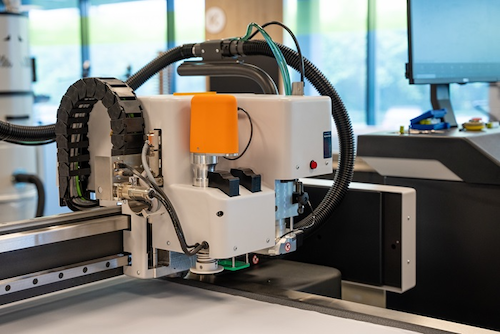

The Kongsberg Precision Cutting Systems (Kongsberg PCS) team will showcase its versatile X24 cutting system and range of advanced tooling.

Visitors to the Media Expo New Delhi (12-14 September) event will discover first-hand how the versatility, power and performance of the Kongsberg X Series of digital cutting tables can enable businesses to boost their productivity and creativity.

‘With a noticeable shift towards more eco-friendly materials, the versatility of finishing equipment becomes crucial,’ said Rafiq Shaikh, Sales and Service Leader at Kongsberg PCS. ‘The Kongsberg machine stands out in this regard, offering cutting and routing capabilities that allow it to efficiently process a wide range of materials with minimal set-up time.

‘This single machine can surpass the production speeds of traditional routers, lasers and plotters, leading to significant savings on labour and floor space,’ he said. ‘By integrating a Kongsberg machine into their operations, businesses can streamline production while staying aligned with the growing demand for sustainable solutions. At Media Expo New Delhi, we’ll highlight how the Kongsberg X24 Edge delivers the flexibility needed to address these current and future challenges, protecting a business’ investment and equipping it for what’s ahead.’

Kongsberg digital cutting tables are engineered for continuous 24/7 operation, ensuring they meet high production demands with flawless finish and precision. With a minimal learning curve, the machines do not require highly sophisticated knowledge or skills to operate, making them accessible and easy to use. Additionally, the operating costs are kept low thanks to their efficient power consumption and minimal need for consumables. This combination of reliability, ease of use and cost-effectiveness makes Kongsberg machines an excellent investment for businesses looking to optimise their production processes.

‘The Kongsberg X24 Edge can easily handle the full spectrum of display, signage and packaging materials from kiss cutting vinyl through to heavy duty milling,’ said Shaikh. ‘There is no sacrifice on machine configuration with all the X-Series options available, and perhaps most importantly the X24 Edge can evolve to keep pace with the changing demands of a business, and those of their customers.

‘At Kongsberg PCS, we are harnessing the latest technology in solutions that meet the challenge of delivering the creative freedom demanded by consumers,’ added Shaikh. ‘Throughout this event, we will demonstrate how the wide range of specialty tools ensure the cutting system can easily handle a wide range of applications to bring the most creative designs to life without compromising on quality.

‘Over the course of the three days, we’ll demonstrate the routing, cutting, creasing and notching capabilities of the versatile table on a range of creative displays,’ he said. ‘What’s more, we’ll do this using a whole range of materials – everything from acrylic, foam board and MDF through to PVC, polycarbonate and vinyl.’

Shaikh said these demonstrations would highlight the versatility of the Kongsberg X24 Edge, cutting more materials with fewer – but specialist – tools, which helps reduce stop time for greater efficiency and productivity, and also reduces wastage.

‘Incorporating the X24 Edge into an existing production not only enables a business to boost its throughput but also gives them the ability to accept any size order run and even expand their offering to drive overall sales,’ he said. ‘This is particularly beneficial for those converters considering a move into packaging, with the Kongsberg X24 Edge having the versatility to switch from sign and display jobs to packaging in next to no time. Not only this, but the modular table can also easily be upgraded with additional tooling, speed and even acceleration to ensure it keeps up with your business demands,’ he said.

|

LOCAL DISTRIBUTOR |