HP unveiled cutting-edge advancements in their HP Metal Jet and HP Jet Fusion 3D printing solutions.

These were unveiled at the recently RAPID+TCT additive manufacturing event.

‘HP is deeply committed to driving the additive manufacturing industry forward with persistent and new enhancements to our existing portfolio,’ said Savi Baveja, President of HP Personalisation and 3D Printing. ‘Our innovations in both metal and polymer 3D printing technologies are testament to our dedication to advancing the capabilities and applications of 3D printing, empowering our customers to turn their ideas into reality with unprecedented efficiency and quality.’

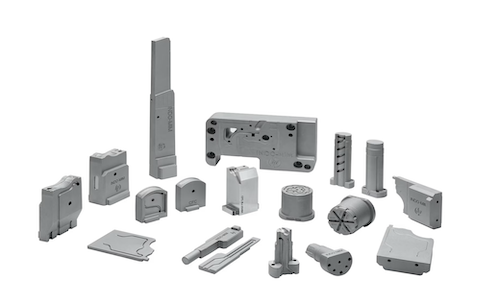

At the forefront of HP’s presentation was the HP Metal Jet S100 printing solution, now equipped with new capabilities aimed at meeting the evolving needs of the industry without compromising print quality. Enhancements to the HP Metal Jet S100 Printing Solution include an increased build height up to 170mm, allowing for the production of larger parts and more parts in a single build cycle, enabling manufacturers to explore new dimensions in product design and innovation.

Additionally, this solution leverages the economies of scale offered by Metal Injection Moulding (MIM) powders, significantly lowering operational and material costs for large-scale production compared to other 3D printing technologies. With new operational efficiency gains in printing process times, the HP Metal Jet S100 Printing Solution continues to advance towards optimal industrial OEE.

HP is also introducing new materials through collaborations with Indo-MIM and Sandvik. These materials include IndoMIM M2 Tool Steel, ideal for high-strength mould inserts and cutting tools, and Sandvik’s Osprey® 316L, which offers improved corrosion resistance and processability for applications in the medical, automotive, and industrial markets. Both materials have undergone rigorous HP qualification processes, helping to ensure reliable performance and accessibility.

In a bid to further democratise 3D metal printing, HP has launched the HP Metal Jet Production Service. This new service is accessible via a dedicated website where customers can submit queries, request sample parts and access comprehensive production services. The service aims to address and overcome common barriers in 3D metal printing, including cost, time and effort, making the technology more accessible and practical for a wide range of industries.

To support this initiative, HP has established a Metal Jet Adoption Center located in Corvallis, Oregon. This centre provides end-to-end application qualifications, from benchmarking and sample part testing to process optimization, helping to ensure that customers can seamlessly transition from prototype to production. HP’s network of Contract Manufactures will play a pivotal role in supporting application development and scaling to serial production.

In addition to these advancements in metal 3D printing, HP is strengthening its strategic relationships with leading software companies. A collaboration with Autodesk has resulted in the readiness of the Autodesk® Fusion® bundle with HP printers, enhancing design and production integration.

Similarly, a collaboration with Altair will provide customers with proprietary HP material information, facilitating better design and production of additive parts. CoreTechnologie’s collaboration with HP aims to elevate texturing for 3D printed parts, providing users with an extensive digital texture library within the 4D_Additive software, pushing the boundaries of surface design.

‘We are excited to help our customers better design parts for HP Metal Jet and HP Jet Fusion 3D Printing Solutions by giving them access to HP material information,’ said Yeshwant Mummaneni, Chief Engineer of Data Management and Analytics at Altair. ‘Through this collaboration with HP, we are creating a bridge across the often-siloed functions of design and production of additive parts so that even more exciting applications can be realised.’

For HP’s polymers and metals customers, a collaboration with Dyndrite will now support HP’s entire 3D printing ecosystem, giving the option to use Dyndrite build manager software to create and submit print jobs. Additionally, HP’s Multi-level build feature included in the process development will allow printing process parameters to be adjusted on a per level basis for up to 20 levels within a single build.

HP is also pleased to introduce the HP 3D Texture Visualiser, developed by Leopoly, a 3D and XR software technology provider. This key component of the HP 3D Digital Texture Library enhances the 3D design process by allowing users to apply and visualize digital 3D textures on their CAD geometry in real time. The tool also supports the import of custom digital textures and provides the flexibility to adjust parameters like scaling, depth, and resolution to achieve the desired look.

Enhancements To HP’s Polymer 3D Printing Platform

As part of a commitment to meet the evolving needs of polymers customers, HP is announcing significant enhancements to its Polymer 3D Printing platform, including materials, features and capabilities for the HP Jet Fusion 5600 Series 3D Printing Solution, designed to address common pain points across the manufacturing process.

Enabling a full material portfolio for the HP Jet Fusion 5600 Series 3D printing solution remains a top priority for HP. Both the HP 3D HR PA12 S, enabled by Arkema and BASF Ultrasint® TPU01 materials, will now be available.

Since the introduction of the HP 3D HR PA12 S material, enabled by Arkema, in March, at the annual AMUG (Additive Manufacturing User Group) Conference, HP has experienced momentum with customers benefiting from reductions in total cost of ownership (TCO) and improved surface finish. For BASF Ultrasint® TPU01 users, HP is delivering up to a 20% reduction in TCO through the enablement of higher refresh rates of up to 90/10 material usage and reduced service pricing of the HP Jet Fusion 5600 Series 3D Printing Solution.

Demand for bright colour part applications with minimal additional post-processing cost remains high among HP polymers customers. To fulfil this need, HP is enabling HP 3D HR PA12 W in the HP Jet Fusion 5600 Series 3D printing solution, designed to enhance colour versatility, manufacturing equipment flexibility and reduce post-processing costs with UV resistance relative to PA12.

This is ideal for part providers and OEMs in industrial, orthotics and prosthetics, and consumer goods sectors who want to dye parts in bright colours. With more material options available on the HP Jet Fusion 5600 Series 3D printing solution platform, customers can further expand their production capabilities and bring new, innovative applications to life.

To overcome challenges associated with Electrostatic Discharge (ESD) in advanced industrial applications, a new ESD print mode will now be available for the HP Jet Fusion 5600 Series 3D printing solution at no additional cost. This feature will allow service bureaus, assembly lines, electronics manufacturers and others to achieve dissipative properties on parts printed with HP Mult Jet Fusion technology. This is enabled thanks to HP Multi Jet Fusion’s voxel-control agent capabilities, meaning that customers will not need additional HW to receive these benefits.

HP continues to prioritise maintaining a low TCO for its Multi Jet Fusion technology with improvements to both the HP Jet Fusion 5600 and 5000 Series 3D printing solutions. In order to address acquisition costs for customers interested in adoption, the HP Jet Fusion 5000 3D Printer specifically will now support an increased variety of materials, including HP 3D HR PA11, HP 3D HR PA12 S, enabled by Arkema, HP 3D HR PA12 GB, HP 3D HR PP enabled by BASF with a manual workflow, and BASF Ultrasint® TPU01 and Estane® 3D TPU M88A with a processing station, further enhancing its versatility and cost-efficiency.

With a lower point of entry for the HP Jet Fusion 5000 3D Printer, customers can more easily adopt HP’s technology and upgrade to a more productive printer like the HP Jet Fusion 5600 3D Printer once applications scale.

On the HP Jet Fusion 5600 Series 3D printing solution, HP continues to reduce idle times between consecutive prints, and now customers with the HP Jet Fusion Automation Accessory will benefit from improved fast swap capabilities, further contributing to cost savings, especially in high-volume production environments.