Print service providers no longer need to choose between sustainability or high quality and production. HP Latex technology features the greenest credentials of any printing solution as well as incredible efficiency and productivity. By adding HP Latex technology to their print arsenal, businesses can print on virtually any substrate to create signage, vehicle wraps, décor, stickers, posters and more. Users can do all of this, and lead with the most environmentally certified technology (1). This article appears in the September/October Sign Africa Journal.

Making Print Services Greener And More Sustainable

HP’s newest Latex technology carries a broad set of credentials that address the full spectrum of environmental concerns: from ink chemistry and indoor air quality, for both print production and display, to lifecycle considerations, earning recognition for products as environmentally preferred overall. It is the most environmentally certified technology (HP Latex Inks were tested for Hazardous Air Pollutants, as defined in the Clean Air Act, per U.S. Environmental Protection Agency Method 311 (testing conducted in 2013) and none were detected).

The technology also allows for application versatility. Users can print on just about any substrate and get scratch-resistant, durable prints with HP Latex inks. The scratch resistance and image permanence was tested by HP Image Permanence Lab. With HP’s high-efficiency curing system, prints come out dry and ready-to-use.

HP Latex ink is water-based, this means it contains no hazardous air pollutants (HAPs), as is the case with solvent-based inks, and as such requires no hazard-warning labels. Even better, it produces odourless prints that are easy to work with, even in indoor spaces, without special ventilation. Odourless prints made with water-based inks are suitable for use in environments such as schools, hospitals, and other places with stringent health and safety criteria controlling the use of solvents.

HP has named Midcomp as an Amplify Impact 3-Star Catalyst Partner for driving sustainability. From training their employees to leading their sales with sustainability, Midcomp are helping customers make an impact through more sustainable choices, knowledge and technology.

A Few Of The HP Latex Product Highlights

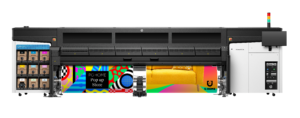

HP Latex 700 And HP Latex 800 Printer Series With White Ink Option

This series responds to the need, and rising demand, for more sustainable large format printing systems. Designed from the concept stage with environmental sustainability in mind, the new printers are ENERGY STAR® rated, so users can rely on them for outstanding energy efficiency. The printers also use innovative HP Eco-Carton ink cartridges instead of conventional plastic ink cartridges. This delivers an 80% reduction in plastic consumption across the device’s lifetime and achieves 66% C02e reduction (based on moving from a plastic ink cartridge to a cardboard HP Eco-Carton ink cartridge). This series also features the best white ink in the industry. Users can print stickers and window graphics with unsurpassed white, as well as save time and reduce ink waste with automatic white ink recirculation and printhead cleaning. Like HP’s Latex 2700W and R2000 models, the white doesn’t fade or yellow over time. Other production printers include the HP Latex 300 series.

HP Latex Print And Cut Plus Solutions

The HP Latex 315 and HP Latex 335 Print and Cut are complete solutions that feature outstanding print and accurate cut with downforce up to 600 grams. Users can save 50% more media with True Shape Nesting and create new applications in three easy steps with HP Applications Centre. Save 50% of the time by printing and cutting simultaneously (based on internal HP testing). Users can also produce output twice as fast and deliver the same day as HP Latex technology ensures that prints come out dry so they can be cut/laminated immediately.

Industrial Roll To Roll And Flatbed Printers

HP Latex 2700W

The new 3.2m (126 inch) wide printers take production efficiency to the next level, offering vivid colours at up to 89sqm/hr (958 square feet/hr) via symmetrical double printheads, which come equipped with automatic printhead cleaning technology. All devices in the Latex 2700 series run on fourth generation HP Latex ink, bringing UL ECOLOGO® certification, while also meeting UL GREENGUARD GOLD and Toy Safety requirements. This allows print service providers to embrace jobs in even the most sensitive environments.

The HP Latex 1500 printer’s accessible print zone with LED lighting and status beacon enable at-a-glance monitoring from near and far.

The HP Latex 3600 is designed for larger PSPs needing long-run, uninterrupted printing and can handle production peaks of up to 35,000 square metres per month.

HP Latex R Printer Series

With this printer series, users can transform any rigid or flexible substrate with amazing colours. Users can also expand their portfolio into a wide range of applications with the glossiest white that resists yellowing. There is no waste between white jobs with removable HP Thermal Inkjet printheads stored in an offline rotating chamber. The printer ensures users are always ready to print white because automatic recirculation and printhead cleaning eliminate manual purging.

Zünd Cutters Provide Maximum Productivity And Sustainability

Power consumption is a major concern in the South African market, with businesses being affected by load shedding. As the most efficient cutters on the market, Zünd cutters use vacuum turbines instead of pumps to minimise power consumption, and provide the highest productivity during limited power as a result of load shedding.

Zünd’s cutting systems and software combine to form an unbeatable solution that fits seamlessly into a PSP’s production process. Zünd’s modular systems enable flexible planning and their versatility creates maximum profitability. Users can achieve superior productivity with digital cutting as well as high quality and precision, and enjoy simple and intuitive operation and tailor-made automation.

The Zünd Q-Line is the latest range in the portfolio, with the Q-Line with BHS180 raising the bar for industrial, pallet-to-pallet production. Zünd won the 2023 Red Dot Award for Product Design for its Q 32-32 D cutter, the flagship product in the newly launched Q-Line. The internationally renowned prize recognises superb quality and is exclusively awarded to products that feature outstanding design.

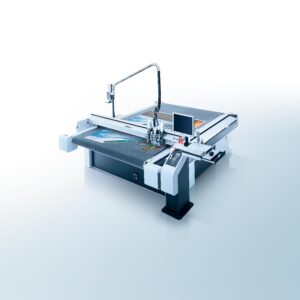

Zünd L3 Digital Cutter

This is an ergonomic solution for leather cutting and apparel and features high-speed punch tools, a slanted work surface and superior precision. With an oscillating tool and the perfect blade for the job, Zünd L3 leather cutters let users process leather and other materials at speeds of up to one metre per second. Sizes: L3 C-40: 2300 x 1000mm and L3 C-56: 3240 x 1000mm.

Zünd S3 Digital Cutter

The S3 cutter system is fast and ideal for signage and graphics, packaging, apparel and technical textiles. Whether used as textile cutting equipment, for vinyl cutting or for the processing of composites, this series’ exceptional processing speeds are the result of intelligent control technology, an advanced drive system, and sophisticated tooling. Sizes (W x L): medium (1330mm x 800, 1200, 1600); large (1800mm x 1200, 1600mm) and XL (2270mm x 1200mm).

Zünd G3 Digital Cutter

This system features uncompromising performance and precision and excels in delivering both exceptional productivity and unsurpassed cut quality. Fully automated board loading and unloading provides the ultimate in workflow efficiency. Ideal for: signage and graphics, packaging, apparel, leather goods, composites and technical textiles. Sizes (W x L): medium (1330mm x 1600, 2500mm); large (1800mm x 2500, 3200mm); XL (2270mm x 1600, 3200mm) and 2XL (2750 x 1600, 3200mm).

Zünd D3 Digital Cutter

The cutter is ideal for larger format production, signage and graphics, packaging, apparel, composites and technical textiles. Featuring an innovative dual-beam system, the two beams can each be equipped with up to three different modules, potentially doubling the throughput. Sizes (W x L): large (1800mm x 3200mm); XL (2270mm x 3200mm); 2XL (2740 x 3200mm) and 3XL (3210 x 3200mm).

Midcomp’s Offerings To Help Its Customers Grow

PPU And PPUGRO

With Midcomp’s exclusive Pay Per Use (PPU) comprehensive and customised programme, users can enjoy peace of mind with no unexpected costs and subscribe to a fixed monthly cost per square metre based on their location. There is no minimum print volume required. PPU covers a user’s ink supplies, printheads, cleaning cartridges, services maintenance kits, labour and spare parts, and is an ideal solution for cost-efficient printing.

With PPUGRO, Midcomp will install a printing system at a customer’s premises and simply charge them a predetermined variable rate per square metre that the customer prints. At the end of every month, a customer will be sent a spreadsheet detailing the jobs they have printed in that month as well as the total square metres printed. Midcomp applies the variable rate per square metre and sends a customer one invoice.

One of the many ways Midcomp aims to support their customers is with services offered at their Innovation Hub (iHub). ‘For over five years, Midcomp has offered a Disaster Recovery Service to our customers such that our customers’ production does not have to be impacted by downtime. We also extended our Value Add Services to include Overcapacity Relief.’

‘Under this programme, our customers’ peak demands are alleviated by using our iHub to help them complete their production on time and maintain their own customer relationships. Our iHub is world class, demonstrating the latest and greatest technology in digital printing and finishing. Customers and potential customers also enjoy the ability to test various media and processes in our iHub,’ said Rob Makinson, Group CEO, Midcomp.

1) Applicable to HP Latex technology compared to competitive large format printing alternatives using solvent and UV technologies.

|

LOCAL DISTRIBUTOR |