Graphix Supply World showcased its long-awaited Mimaki JV400-LX Latex printer at the Sign Africa RoadShow in Cape Town from 20-21 June. The printer generated a large amount of interest from visitors, with five units being sold at the RoadShow. The company also showcased a number of groundbreaking new print solutions from Mimaki.

In addition to the five sales the show, many other deals were signed and with more sales in the pipeline, GSW declares Sign Africa Cape Town RoadShow a resounding success.

The company won the runner-up for Best Large Stand award. VIP Mimaki representatives, Mr Kurosawa and Mr Horiguchi of Mimaki Japan were present to show their support of new products and for GSW, which is the Mimaki African dealer.

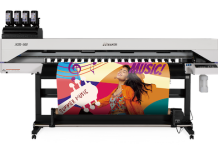

The Mimaki JV400-LX Latex printer was showcased printing onto unconventional substrates not usually associated with Latex printing, due to media deforming under high ink-curing temperatures.

When Latex was first introduced to the market, it was hailed as the new ‘eco-friendly’ solution, which was set to replace solvent ink printers in the large format printing market. Due to the high temperatures needed to cure the water-based Latex ink (80°C-100°C), a lot of power was being drawn to heat up the Latex printer, resulting in high operating costs and increased electricity usage.

In addition, the original Latex printers are only able to print on a limited range of OEM approved media, due

to high temperatures deforming heat-sensitive medias. Continuous costly head changes which need to be replaced every four litres also added to the drawbacks associated with the original Latex printers.

Mimaki’s revolutionary new JV400-LX Latex printer has solved all of these problems, and offers improved functionalities and white ink. Now, printing onto clear substrates can be achieved with full colour impact, thanks to the world’s first white Latex ink, developed by Mimaki.

Show attendees were particularly interested in the lower operating costs of the Mimaki JV400-LX thanks to lower curing temperatures of the ink (40°C -60°C), new head technology (heads only need to be replaced after one year) and a wider range of applications possible, as heat-sensitive media can now be used.