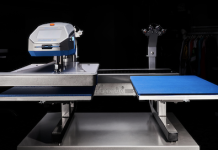

The Graphics One family of Xpress heat presses continues to grow with the latest release of its dual platen semi-automatic heat press. The GO Xpress 1620DS basically provides two heat presses for the price of one. This dual platen heat press is unique with its two 40.6 x 50.8cm (16 x 20”) manual moving platens for ease-of-use and ease-of-mounting.

Over the past few years Graphics One has found the requirements for heat pressing and curing of garment decoration has increased exponentially. In fact, many users are now buying multiple printers but are discovering that the biggest bottleneck for garment production is the heat press. The new GO Xpress 1620DS Heat Press substantially improves the heat press workflow by allowing two platens to be operated very easily by one person. The ergonomic design of the dual platen system enhances the threading and mounting of substrates for a far more efficient workflow.

With the addition of the GO ColorMate DS RIP to the DS-2400 system, the turnkey system now includes RIP, printer, ink, paper, software, training and support. Additionally, the printer is capable of imaging both dye sub to cotton and dye sub to polyester out of the box using the included GO Fuze solution.

– Double production with unique ergonomic design with lower platen movement.

– Increase efficiency by mounting one platen while second platen being pressed.

– Stationary heat press dead with automatic up / down pressing.

– Lower platen movement easier to use than dual units with heat press head movement

– Advanced digital LCD screen with timing, temperature, counting and alarms.

– Industrial grade construction for long lasting durability.

– Exact pressure control up to 150 PSI.

– Requires air compressor (not included).