While mechanical engraving machines have their advantages, especially with metal surfaces, there are limitations when it comes to acrylic, leather and paper. Trotec Laser outlines five reasons why a laser engraving machine is the ideal addition to future-proof an engraving company.

1. A laser engraving machine is easy to operate

Operating a mechanical engraving machine requires special knowledge and experience. A laser machine, on the other hand, is very easy to operate.

2. A laser machine has an infinite number of possible applications

The mechanical engraving machine impresses with the processing of metals and with deep engraving. A laser engraving machine can process an almost infinite number of materials such as: wood, glass, paper, textiles, metals, stone, acrylic, leather and much more. In addition, you can cut as well as engrave with a laser machine.

3. Buy a laser engraving machine and increase your productivity

With a laser engraving machine you can engrave and cut multiple workpieces at the same time. Different engraving patterns are also possible in one operation. Save your graphic files and use them over and over again. This saves valuable preparation time and results in creative freedom.

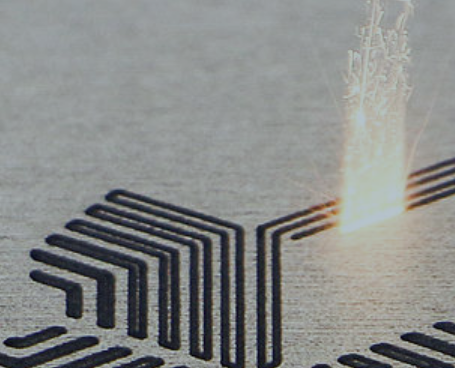

4. High precision of the laser

Laser technology boasts maximum precision: engrave the finest details and the smallest fonts. You can also cut filigree and complex geometries with the non-contact laser technology.

5. New products: photo engraving personalisation

A laser engraving machine allows you to expand your product portfolio. For example, you can engrave photos on acrylic, leather or wood.

TROTEC LASER

https://www.troteclaser.com/