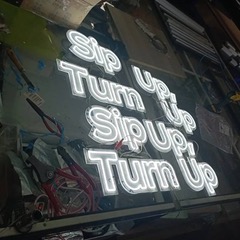

Exion Corp has launched its three-part Neon Flex System, an efficient and customisable option for the market. It is available in either 6mm or 8mm Neon effect LED with silicon. Its system includes the acrylic or Foam board backing, the zigzag LED strip and the Neon Flex silicone tubing, offering the traditional neon look when combined.

Exion Corp’s Neon Flex Fabricator, Frans Mafamba, shared his experience in manufacturing Neon Flex LED Signs at Exion Corp, ‘While it is a straightforward process, there are certain things that you need to take into consideration to ensure that a high quality sign is produced’.

‘The first step is to ensure that your CNC bed is 100% levelled. The consequences of grooving your acrylic sheet on an unlevelled bed would be unpleasant, you will find a very inconsistent depth across the entire groove, not achieving the 4.2mm depth that you want, and ultimately resulting in a sign of poor quality.’

‘The process of manufacturing is simple, you groove your 6mm or higher acrylic backing to a depth of 4.2mm with our specialised CNC bit, manufactured for the sole purpose of grooving acrylic for Neon Flex fitments. This bit creates a lip on either side of the grove so that the Neon Flex can easily clip on and stay in place.’

He continued, ‘Thereafter, you drill an exit hole for the power cable in the most inconspicuous place before applying the LEDs into the groove via its self-adhesive strips and internally wire up and join the LEDs to ensure that you have just one input power cable.’ Mafamba suggested that transparent cables be used to minimise the visibility of joins, which can take away from the overall beauty of the sign.

‘Lastly, you clip in the silicone Neon Tubes to the lips created by the CNC bit above the LED Strips. Once clipped, you assess and mark the areas that require reshaping. We have two tools for this. The 90 degree graver tool is used for reshaping sharp bends and corners to ensure that you have a flush fit and eliminate light leakage. We also have the Round Tool, which is used to the finish edges of a letter or shape that is not going to be connected to another part of the sign’, concluded Mafamba.

Exion will demonstrate how to make Neon Flex Signs at the upcoming Sign Africa Cape Town Expo, which will be held at the CTICC from 3-4 May.

EXION CORP

+27 11 464 5053

admin@exion.co.za

https://www.exion.co.za/