The new EFI VUTEk FabriVU 340i is an advanced, aqueous dispersed dye-sublimation printer. Features include a new platen and extraction system that enables in-line heat press sublimation directly from the printer.

EFI customers gain greater convenience and value, as it is available at a price that is less than the cost of a comparable printer and heat press purchased separately. Plus, the combined printer/heat press system uses less floor space than would be required with separate printing and sublimation stations.

The new offering continues a track record of innovation and customer success worldwide with VUTEk FabriVU aqueous dye-sub printers – a best-in-class technology based on EFI Reggiani’s 70+ years of innovation in textile printing.

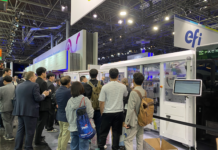

FESPA attendees also witnessed the next generation in digital print job management with version 7 of EFI’s Fiery wide- and superwide format production digital front ends (DFEs) and updated Fiery Command WorkStation® software. Together, these two products help unify production operations by giving users the ability to manage cut-sheet, continuous-feed, wide-format, and superwide format digital print devices from a single user interface (UI).

‘We were excited to show the continued advances of our soft-signage portfolio at FESPA,’ said Ken Hanulec, vice president of marketing, EFI Inkjet.

‘Our new in-line innovation for this product line creates direct-to-fabric prints that are immediately ready for finishing or shipping. By combining two major production steps into one continuous process, our customers can drive greater throughput and take full advantage of the rapidly growing soft signage and fabric printing market.’

‘EFI has just sold our very first VUTEk 340i printer,’ Hanulec added, ‘and it has taken us to a significant milestone, as it is the 100th VUTEk FabriVU aqueous soft-signage printer sold worldwide.’

Dublin, Ireland-based CoverUp Ltd is the first company to purchase the 340i model printer. The company chose the 340cm (133 inch) wide device to take its soft signage capabilities to the next level of quality and productivity.

‘We were looking to increase our soft signage printing capacity with a reliable printer with inline fixation,’ said CoverUp operations director Anthony Byrne.

‘We flew to EFI Reggiani in Italy to see one of the very first VUTEk FabriVU 340i demos, and found the printer to be a significant upgrade in terms of image quality, productivity and reliability compared to our existing fabric printers. The addition of this latest technology from EFI is going to give us a significant competitive advantage in our marketplace.’

The new printer provides the high quality of EFI VUTEk FabriVU aqueous dispersed dye-sub printing with sublimation completed in-line at fast production speeds. Customers who occasionally need to print to transfer paper and then sublimate offline can use a special direct-to-paper mode on the 340i model for printing only.

In addition to the new VUTEk FabriVU printer, EFI’s exhibit at FESPA will include technologies from the company’s leading portfolio of VUTEk LED inkjet and Reggiani industrial textile digital printers – all driven by the latest EFI Fiery digital front end systems.

Pigment ink technology

EFI’s exhibit also featured the launch of a breakthrough industrial textile pigment ink technology for direct-to-textile production. The new EFI Reggiani pigment ink technology gives users a faster, environmentally friendly production process with inline polymerisation that requires less water, less energy and less processing time, with no washing or steaming needed. In addition, the ink’s excellent fastness properties and high printability sharpness will allow printing on a wide range of fabrics with the fine-detail designs.

The new pigment textile technology completes the outstanding range of innovations EFI Reggiani has presented over the past year, with unparalleled new products including the FLEXY digital printer launched at last year’s FESPA tradeshow and the brand-new EFI Reggiani COLORS printer launched last month.

H Series

The new VUTEk h series of 3.2-metre wide hybrid LED printers launched at FESPA is the culmination of EFI’s decades of experience in signage and graphics production technologies as the world’s leading manufacturer and developer of UV and LED inkjet superwide format printers and inks.

The printers’ new, high-velocity 7-picolitre UltraDrop Technology greyscale print head imaging delivers precision dot placement and consistency from print to print at high production speeds. The printers offer four- and eight-colour printing modes plus white, as well as five-layer print capability in a single pass.

The new VUTEk h3 model offers maximum throughput of up to 74 boards per hour. The h5 model, which is available direct from EFI or as field upgrade to the h3 model, can produce up to 109 boards per hour.

The new EFI Reggiani pigment inks are based on an innovative new binder technology. The inks react to EFI Reggiani printers’ on-board dryers, which set off a unique in-line polymerisation process for faster, greener printing that requires fewer steps than other digital industrial inkjet textile systems.

The new pigment textile solution extends the outstanding range of EFI Reggiani innovations presented during the last 12 months, including the EFI Reggiani FLEXY launched at last year’s FESPA, and most recently, the EFI Reggiani COLORS – a breakthrough printer offering up to 12 colours that brings new creativity to the industry with unmatched printing quality and uniformity, an extended colour gamut, superior colour depth and increased penetration into fabric.

EFI Reggiani printers are part of a complete EFI Ecosystem mini-factory application that were shown at FESPA. The design process of the EFI Ecosystem starts with EFI Optitex, a technology innovator in the field of 2D/3D software. The cutting-edge digital solutions offered by EFI Optitex allow brands to optimise their workflow and create patterns in the digital sphere, ultimately saving time, money and textile, which places EFI Optitex’s clients at the forefront of the textile industry.

Once a virtual product pattern is complete, EFI’s Fiery DesignPro software – a series of plug-in applications for Adobe Illustrator and Adobe Photoshop – combines technologies for efficient textile design and file preparation with the Fiery proServer DFE for professional colour management and high-quality RIP output on EFI Reggiani digital printers.

Efficient, high-quality production in the EFI Ecosystem for textile at FESPA takes place on the EFI Reggiani FLEXY, a versatile printer that handles a wide variety of fabrics, from knitted and woven to low- and high-stretch materials. The tightly integrated mini-factory gives textile producers a smoother, coherent, production-aware workflow by connecting EFI technologies as well as key workflow and cut-and-sew solutions from other leading vendors for true end-to-end productivity.

Show attendees that visited EFI also experienced EFI’s 360-degree, interactive virtual reality (VR) demonstrations of the EFI VUTEk HS125 Pro hybrid inkjet press and EFI’s game-changing, single-pass corrugated packaging press, the EFI Nozomi C18000. The ultra-high-speed (75-linear metres per minute) Nozomi press has multiple installations worldwide and is used to drive digital efficiencies in digital packaging production at some of the world’s leading corrugated board converters.

Upcoming FESPA events include FESPA Africa, the region’s largest, focused exhibition for wide format digital printing, screen printing, garment decoration and textile printing, which is co-located with Sign Africa and Africa Print, the region’s leading events for the signage industry. The event is taking place from 12-14 September 2018 at Gallagher Convention Centre, Johannesburg.

|

LOCAL DISTRIBUTOR |