The ReNOIR NEXT System a highly versatile product that prints onto fabrics and papers using the same ink set with a 1.8m belt-less digital printing system.

It joins the highly successful Reggiani line-up of textile printing solutions and offers simplified material handling, a compact footprint and lower acquisition cost, making it an ideal entry-level production device. Like other EFI Reggiani printers, its high quality sublimation inks are complemented by its ability for high-speed throughput with the lowest total running costs.

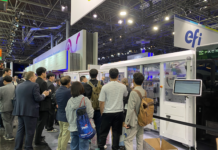

EFI Reggiani is revealing the new digital printing system at the first dedicated textile exhibition since the mid-2015 acquisition to form EFI Reggiani. The company is also showcasing other new technological sustainable solutions and processes for the new era of green textile factory production at ITMA 2015.

EFI Reggiani’s strong position, and long and successful history as a leading manufacturer of high-end digital textile machines, has resulted in a comprehensive range of systems used worldwide for a growing range of fabric applications. The company’s innovative philosophy is founded on decades of extensive research and now targets end-user demand for consistent superior quality and fast productivity. This is achieved successfully through the optimisation of the textile manufacturing process with reduced energy and water consumption, leading to greater efficiency and a lower environmental impact.

Dr. Ambrogio Caccia Dominioni, managing director, EFI Reggiani explained, ‘Visitors to ITMA will be able to generate a wealth of new ideas, whether they’re first-time investors in digital textile solutions or established fabric specialists. With the key to true integration, our fabric printing and finishing solutions incorporate the highest levels of technological know-how with a solid legacy of chemical knowledge and inks. Analogue textile print companies can place their confidence in us for future versatility in-line with production trends, mass customisation and variable volumes. As a result, customers can grow with digital technology for sampling and production runs while adopting a cost-effective and environmentally friendly business model.’

Technologies on display at EFI Reggiani’s booth include:

• The TOP printer, which features exceptional, industry leading quality with one of the most robust inkjet arrays in the market. Available in both 1.8m and 2.88m widths, this heavy-duty, flexible, fully integrated machine is demonstrated with reactive dyes printing direct to cottons, and is a fast throughput machine that can also be used with acid, disperse, sublimation and pigmented inks, giving it the ultimate combination of versatility and speed.

• The Essetex 2m wide washing box, which is an ideal system for knitted and light fabrics, particularly where print washing is beneficial for delicate textiles and for post-dyeing of printed cloth.

All of these inkjet digital textile systems are based on new eco-chemistry, using water-based inks that, together with advanced and streamlined automation, provide a total solution for textile businesses. The water-based inks are developed to be eco-friendly by significantly reducing pollution without compromising quality and speed.

Also making their debut at the show are new Artistri® PK2600 inks developed by DuPont for cotton textile roll-to-roll printing on EFI Reggiani printers. The new inks offer colour and hand comparable to reactive printing, excellent fastness performance and best-in-class digital printing performance, without steaming or washing production steps that hinder turnaround times.

As a complete solutions company, EFI Reggiani will be demonstrating the capabilities of EFI Fiery production workflow and colour management for the first time with EFI Reggiani products. These valuable components of the EFI Ecosystem are designed to enhance and increase customer productivity and efficiency.

EFI Reggiani’s portfolio of integrated systems is designed and manufactured to the highest standards and to simplify textile production across a wide range of industries, including home textile and interior décor, sports and active wear, fashion, outdoor, automotive, and flooring applications. Plus, the company is addressing the growing demand for display graphics applications and displays where vivid colours, dense blacks and lightweight materials are complemented by more eco-friendly results.