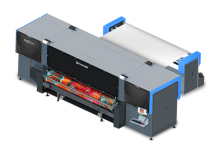

The SubliXpress Plus comes with 8 staggered Kyocera heads that can print variable drop sizes of 5, 7 and 12pL as demanded to produce exceptionally sharp lines and create smooth gradients in colour tones.

The high-speed, high-quality printing with minimal ink consumption is a result of decades of experience in manufacturing digital inkjet printers. ColorJet’s proprietary AST and HSTR technology are inherent features of the machine.

Dye sublimation printing is dominant in the digital textile printing sector accounting for almost 50% of all digital textile prints across the polyester and apparel domain. The dye sublimation textile printing market, which was valued at USD 8.1 billion in 2019, is facing a compound annual growth rate of 10.7% during the forecast period of 2020-2025 and is expected to reach a value of USD 14.2 billion by 2025. Considering the need for a high production sublimation printer to mitigate this high demand, ColorJet launched the SubliXpress Plus.

The printer is ideally positioned for existing high-volume dye-sublimation printers and first-time investors looking to upgrade their business with high production machines. The company also foresees a good potential for this zero water-consuming printing technology, which would enhance sustainable garment manufacturing as it would work very well on fabrics made with recycled polyester-knit and woven materials.

On its 1.8m printing width, the machine can handle a wide range of paper starting from 18gsm and above. The Leaf clamp is yet another improvisation to prevent the paper from curving up at the edges when printing. Being able to use low gsm paper and the ability to print on a less than ideal paper rolls with ease, it addresses some major practical shop floor concerns. The vacuum bed, which holds the paper in place, is wider and the suction pressure can be varied.

The two-stage drying system provided immediately after the printing zone stops the paper from puckering even when printing large patches of solid colour. The printer includes features for enhanced productivity, including a 900mm diameter feed roll, high precision servo motor and large rubber roller with pneumatic shafts for a firm grip of the paper roll core. The machine is also equipped with multiple brush rollers to continuously smoothen out the paper as it moves from feed roll to rewinding of printed paper.

The new SubliXpress Plus is equipped with gold plated metal encoder to give more precise inkjetting at high speeds, effectively leading to longer service life. In addition to this, the Active Seaming Technology is used for producing superior quality at high speed.

COLORJET

https://www.colorjetgroup.com/