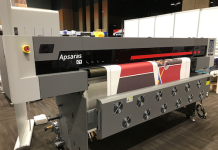

AWT will display a swissQprint Impala printer with new features introduced at FESPA London at the Sign Africa Expo, taking place from 21-23 August at the Sandton Convention Centre.

NINE PICOLITER DROP

This new feature gives users an additional production mode for ultra-exacting photo print work with fine colour gradations, ideal for subjects that require uniform expanses of colour without screening artefacts, and reproduction of fine detail. It fulfils the needs of pin-sharp typography with bravura, too, and all of this with no appreciable reduction in speed compared to the previous highest-quality mode. The output software automatically selects the 9 picolitre droplet size when RIPing print files for fine art applications. With light shades in use, the maximum visual resolution on the substrate reaches 2160 dpi. Small print runs and prototypes may be displayed confidently alongside offset reproductions. The new droplet size is integrated immediately and at no extra cost on the Oryx, Impala and Nyala.

NEW ROLL TO ROLL UPGRADE

This new value-added option allows the machine to print easily on uneven roll to roll media. The machine automatically controls full vacuum on the complete print bed and the media advances using a quick release valve.

SWISSQPRINT TANDEM PRINT MODE

The tandem function keeps the machine running non-stop and makes waiting times a thing of the past. The mode is available for all three swissQprint inkjet systems; Oryx, Impala and Nyala. It is of interest to anyone wanting to achieve the greatest possible output for serial production in digital printing. The principle is straightforward: the print table is loaded as usual from the front and the print job is started. Whilst the machine processes the first job, the operator starts to load the rear half of the table. The printing beam moves to the rear and continues the printing process as soon as the front job is finished and the operator confirms that the rear job is ready to start. The operator meanwhile removes the finished prints from the front area and prepares the next substrates for printing, so production continues until the series is finished. The machine works non-stop without interruption.