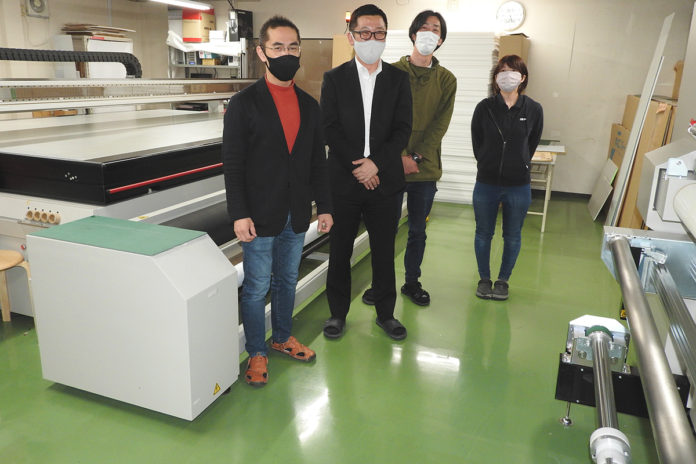

Japan-based company Hataya was founded in 1982 as a silk screen printing company. Since then, it has steadily digitised its operations. By investing in Agfa’s Asanti workflow software for its sign and display printers, the company has become a forerunner in its field.

Asanti has improved the company’s productivity while significantly reducing output errors. An employee who works in the production department of Hataya said, ‘I couldn’t do without Asanti anymore. Even complicated output work can be easily processed using the templates created by the software. Asanti automatically performs a number of output tasks, such as the placement of cut marks. That way, you don’t have to open the files in Illustrator, which reduces output errors. When I opened the artwork in Illustrator, the layers were complicated and locked, so I tended to make mistakes such as moving or erasing objects. The work that took 30 minutes before can now be done in about 10 minutes.’

Another production department employee added, ‘We always have a lot of print orders to process. Thanks to Asanti, I feel that we can proceed faster to the finishing stage, including the cutting process, and that the productivity of the overall manufacturing process has improved.’

Once the workflow has been established, PDFs that have been processed by Asanti, including mark placements, are printed on non-Agfa printers too. It was necessary to make some small adjustments, but since Asanti has a wide range of settings, it was possible to tune it to the company’s operations. At first, they needed to create templates and to set up rules for mark placement and various other tasks, but after these initial efforts, it became easier. Employees can work exactly the same way as before without having to change their operation processes.

In terms of expectations from Asanti and Agfa in the future, the President of Hataya, said, ‘I would like to recommend Asanti to all other printing companies. It has had a huge impact on our operations by shortening lead times and reducing mistakes. Even work that requires an urgent response can be completed well ahead of time, without any mistakes. We believe that it was worthwhile to be able to improve productivity without the need for large investments in equipment.