Imaged Advertising Creations (IAC) has invested in a Jeti Tauro H3300 HS LED with spot varnish capabilities. The press combines vivid print quality with extreme productivity, cutting-edge automation, and low ink consumption. This ruggedly built hybrid press offers the distinctive ability to add a layer of high-gloss or satin varnish to wide format prints.

IAC is one of the leading visual solutions providers based in Toronto, Canada serving the North American market. This printer will allow them to produce high-speed output at near-litho quality.

‘We imagined the stunning visuals we could produce on the Jeti Tauro with varnish and recognised that it would be a great fit for our higher-end clientele,’ said Sean Sadhoo, COO at IAC. ‘This is another first in the industry for us. We are known as pioneers that are always pushing the limit. The new Jeti Tauro press will complement our 5m dye sublimation offerings, turning us into a one-stop shop.’

IAC is an innovator in wide format printing, helping brands enhance their vision through distinctive visual communication offerings. Its knowledgeable team of industry experts takes pride in creating an unsurpassed customer experience while bringing its vision to life. IAC’s ‘figure-it-out-mentality’ has grown the business across retail, event marketing, corporate interior design, and other segments.

The unique gloss and satin finish produced by the Jeti Tauro Varnish enhances prints with a premium and refined look that cosmetic and apparel industries desire, two verticals that IAC has experienced exponential growth within the last two years.

Fred Clemente, VP Sales and Innovation, explained, ‘We recognised during Covid that we can no longer be a one-trick pony serving just one market segment. Diversification of accounts is paramount to our success. Markets such as cosmetics and apparel are hungry for customer-focused companies that have innovative solutions.’

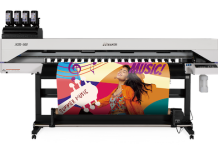

Suited for various rigid and flexible substrates, the Jeti Tauro H3300 HS LED Varnish is a heavy-duty, ruggedly built press that easily handles extreme workloads, multiple-shift operation, and 24/7 printing. This engine produces smooth ‘offset-like’ detailed prints up to 3.3m wide at up to 680sqm/h in four or six colours. Agfa’s high-pigmented GREENGUARD Gold-certified Anuvia UV LED inks provide patented ‘Thin Ink Layer’ technology, resulting in low ink consumption. Jeti Tauro’s Asanti workflow software automates the entire printing process.

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za