It seems like only yesterday that we were all talking about this new and revolutionary printing method, which could print any 3D model made in 3D software. Everybody was amazed with the idea of creating any piece straight out of your imagination in a tangible way, exactly like you wanted it.

3D printing has existed since 1980, but the real explosion for this technology was about 10 years ago, and it has continued to evolve. It’s amazing how 3D printing has been developing and has continued to expand, but even though it was really innovative from the beginning, 3D printing also had its disadvantages, and it wasn’t necessarily something everybody needed in their businesses. Finishes were not as clean as other prototyping options, the printing speed was not that convenient and other aspects made the whole 3D world a little doubtful and unstable to the market’s eyes.

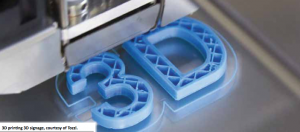

Gradually, 3D has made its way through a wide range of industries that go from making medical casts, to creating amazing looking food, or even glass pieces. All of these discoveries for different kinds of applications have forced the 3D business to step up and provide a better service in general, tons of new options on brands and new materials (keeping the common ABS and PLA plastics), new software, finishes, etc.

Having that said, it is obvious that the future waits for a notable increase in the additive manufacturing industry. It’s exciting to discover what’s next for 3D printing and what 2020 is bringing to it. Manufacturers are working on new developments that will expand the performance of machines and the different dimensions of them.

Faster Printing Methods

In order to achieve a greater production volume, printing speed should be improved since today’s machines aren’t as fast and the relation of speed-size of the piece is considered really slow. Impossible Objects, a brand founded by Bob Swartz, has been working on getting a faster speed for the printers by trying some properties of 2D printing. Last year, they launched a machine that is supposed to be ten times faster than traditional 3D printers on the market. We can expect other big brands to try and match this in 2020.

Cabins Will No Longer Have A Size Limitation

Many brands create 3D printers with a cabin that controls the temperature and humidity, and also keeps away different particles. This creates a limitation when talking about the size of the objects a 3D printer can produce. MELD Manufacturing has developed some machines that do not require these types of chambers, leaving a wider space for printing. This will not only speed up mass production, but will also allow printers to get complete pieces without having to combine a lot of them and removes the process of joining them all.

Wider Variety Of Materials

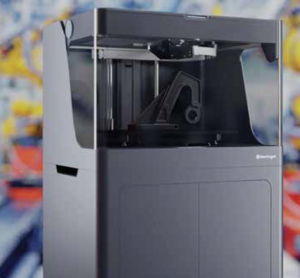

There are a lot of new applications on the 3D market, but the range of materials is increasing every year. Markforged has created machines that can print different types of metals, nylon, superalloys and chopped carbon fibre. Impossible Objects has also partnered with BASF to accelerate the process of developing new materials for 3D printing. This creates opportunies for many more industries to implement 3D printing in their businesses.

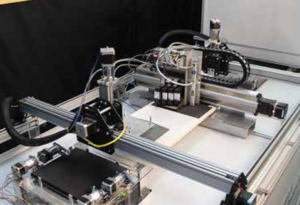

Software Upgrades

Software plays a big role when it comes to 3D printing. Not only does it allow you to modify some components of the design of the piece but to make changes to the temperature, finishes and add extra material for support when printing. It is very clear that some software can provide a super clean finish of the pieces, when other ones don’t.

Essentium is already checking materials and big mass production protocols through software. Markforged developed kind of a cloud-based process in which a designed piece can be produced anywhere else in the world. This also creates a huge facility for industrial production. It is expected that new software solutions will include greater security, remote collaboration and manufacturing precision.

3D Printing Will Grow In Partnerships And Collaborations

3D is growing constantly and developing its full potential. This will lead to new companies, startups, and companies with different backgrounds and expertise to join the 3D world. As mentioned before, Impossible Objects and BASF will collaborate to develop new materials for additive manufacturing. 3D printers represent a challenge for industrial designers and engineers to create and redesign new machines with tons of new features.

The future looks tempting for 3D printing and it’s one of the most transformational and innovative technologies of the fourth industrial revolution. So we are definitely going to see greater things in the future for additive manufacturing in the 2020’s.

Submit your news and video content to journo@practicalpublishing.co.za

Subscribe to our YouTube channel, read the top 5 stories weekly on WhatsApp or sign up to our newsletter.

FLAAR REPORTS https://flaar-reports.org