X-Rite Incorporated and Pantone LLC have announced Textile Color Hub, a groundbreaking solution to make digital colour specification more efficient, achievable, compliant and sustainable across the design to production workflow.

For most textile brands, colour specification is a painstaking and subjective process. In a traditional workflow, brands and designers select colours and send a physical sample for suppliers to match. The supplier creates multiple lab dips and ships the options back to the brand for approval. This cycle can repeat multiple times, leading to unnecessary delays and excess waste that increases the carbon footprint of the textile industry.

‘The future of textile colour approval and production control lies in a cloud-based, data-driven, digital workflow,’ said Pieter Mulder, Global Strategic Account Manager, X-Rite and Pantone. ‘The X-Rite Pantone Textile Color Hub transforms the way brands and suppliers communicate and collaborate to bring products to market up to five times faster. It paves the way for a modernised, digital approach to specify and approve textile designs while reducing waste and carbon footprints.’

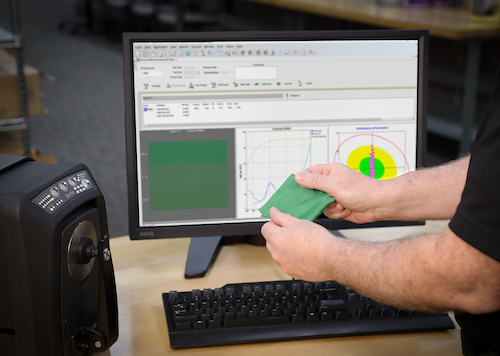

Textile Color Hub enables brands to combine their traditional and isolated solutions into a complete digital colour workflow to securely communicate and control specified colours and designs. It is an open, cloud-based ecosystem that supports spectrophotometers from X-Rite and other manufacturers.

The brand selects a Pantone colour or any private brand colour for a new design, and creates a Colour Specification Document using a pre-defined template that includes the spectral data for the specified colours, the required DeltaE tolerances, and the illuminants to measure against.

Selected suppliers are automatically notified of a new design through Textile Color Hub and use the Colour Specification Document to begin colour formulation and the lab dipping process. The platform compares the specified colour against the measured best lab dip. Suppliers then submit through Textile Color Hub for digital approval by the brand.

Textile Color Hub offers a smarter, more sustainable solution that streamlines colour management. It brings measurable benefits and value to textile brands and suppliers, including: getting 95% of lab dips right the first time, reducing waste with only one start up and wash up, reducing Co2 with one dip and zero physical samples, and improving time to market by 75%.

‘Textile Color Hub is used by one of the world’s largest textile and furniture retailers and delivered immediate results for both the brand and its suppliers,’ continued Mulder. ‘It is fast and easy to implement and with a digital colour workflow, companies can start production in days instead of weeks.’

DIGITALVIEW

+27 11 462 4849

mark@digitalview.co.za

http://www.digitalview.co.za