Bradley Pulford, VP and MD of HP Africa, outlines how digital manufacturing and 3D printing can support African economies. He also gives his predictions on the development of the digital manufacturing sector in 2021.

Africa started to deploy 3D printing over a decade ago and today there is even bigger potential for additive manufacturing on the continent. The rise in 3D printing also means that there is greater demand for customisation, meaning that manufacturers will need to produce personalised products on a mass scale at competitive prices.

Nine out of 10 global respondents (91%) in the HP Digital Manufacturing Trends Report noted that they would pursue mass customisation if they could personalise parts via 3D printing. Case in point: SmileDirectClub is digitally transforming the $12 billion orthodontics industry using 3D printing to print dental aligners and Cobra Golf is disrupting the sports industry by building on a rapid shift toward product personalisation to produce a first of its kind 3D printed commercial putter.

There will be an uptick in new software innovations that provide manufacturers with the tools and infrastructure to enable digital manufacturing at scale, leading to greater productivity. Advancements in software and data management will continue to drive improved system management and part quality, leading to better customer outcomes.

Fifty five percent of global respondents in the HP Digital Manufacturing Trends Report reported that ‘accelerated innovation’ will see the most advancement over the next five years, followed by 52% who said quality management will advance data and software and 50% who agreed data and software will enhance design for additive capabilities.

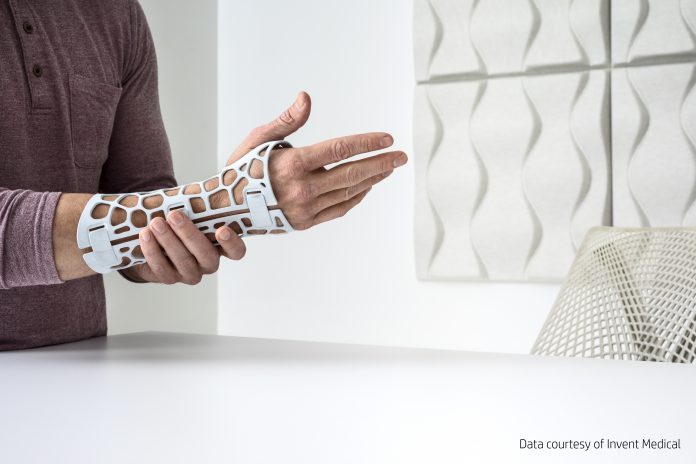

The $50 billion health and wellness industry is poised to see the most advancement in 3D printing in 2021. There is nothing more personal than the human body, and the opportunity to deliver highly personalised 3D printed parts such as orthotics, footwear and other applications that integrate biomechanical data will be critical. These materials provide health and wellness professionals with ultimate control over the components produced and limitless possibilities in design.

In South Africa, we collaborated with our partner Mentis 3D to increase production of 3D designs to meet urgent healthcare needs during the Covid-19 pandemic. Mentis 3D’s full range of HP MJF machines are being used to produce high volumes of medical materials like face shields, goggles, cloth face mask clips and a large variety of Venturi valves with different specifications for respirators.

Fifty-five percent of global respondents in the HP Digital Manufacturing Trends Report predict that the health and wellness industry will achieve the most innovation in the next five years.

We will also see significant interest in digital manufacturing technologies across regions when it comes to economic growth, and it is no surprise why: manufacturing is the engine that supports entire economies and ecosystems.

Nearly all global respondents (99%) of the HP Digital Manufacturing Trends Report believe that digital manufacturing technologies can lead to economic growth. Manufacturers are backing this belief with their budgets, with nearly three quarters (71%) of respondents planning to invest in digital manufacturing technologies by the middle of 2021, and 85% indicating their company is planning to increase its spending on 3D printing.

To continue advancing the industry and grow the population of practitioners, digital manufacturers must offer more professional training to more workers, and collaboration is fundamental to 3D printing. As companies look to deliver more value to end companies, they will form new alliances and operate within new ecosystems.

Two-thirds of the HP Digital Manufacturing Trends Report’s global respondents (64%) said more professional training services should be offered to further 3D printing. Additionally, cross-sector collaboration is critical to the future of digital manufacturing, according to 85% of respondents.

Sustainability continues to be a key metric for business operations. As small businesses, governments and large enterprises increasingly assess and track their environmental impact, digital manufacturing is expected to play a key role.

Half (50%) of the report’s global respondents indicated 3D printing’s ability to reduce waste, lower carbon dioxide (CO2) emissions and promote a circular economy. In addition, 3D printing enables localised manufacturing, helping reduce the complexity and environmental impact of supply chains.

When it comes to new materials and tooling capabilities, 3D printing not only is a more precise mechanism, but it also supports designs and structures that are complex and customised, making fabrication seamless. From reduced costs to improved functionality, new tools are a promising source of innovation that will continue to grow in popularity in 2021.

According to the report, heat-activated 4D printed parts, in particular, will show the most innovation and advancement in 3D printing over the next five years. Nearly half (48%) of global respondents say these ‘smart’ parts have the most potential for advancement among 3D printing technologies.

HP

www.hp.com