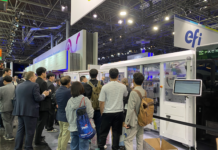

Kansas based Custom Color Corp. has reported the installation of an EFI VUTEk HS125 Pro hybrid flatbed/roll inkjet press and an EFI Fiery proServer digital front end (DFE).

The new 320cm (126 inch) wide, high-volume press offers the consistent, high-volume, high-definition imaging needed for the company’s core business. With the addition of the HS125 Pro, Custom Color Corp replaced an older, dedicated flatbed printer. Mike Lecus, Custom Color’s COO said, ‘We continue to invest in next level technologies to provide our clients with the highest-quality products on time and on budget.’

Printing at speeds up to 125 boards per hour, the VUTEk press has eight channels, including two with white ink, and delivers premium-quality, greyscale imaging on a broad range of flexible and rigid substrates up to 5cm (2 inches) thick. ‘The HS125 Pro increases our capacity three to four times on UV-printed work,’ said Lecus.

The newly installed hybrid printer is also doing double-duty on roll-to-roll goods. The new press is just the latest investment in EFI technology at Custom Color. At the start of the year, the company underwent a major upgrade in fabric soft signage production, with a pair of EFI VUTEk FabriVU 340 aqueous dye-sublimation printers. The printers have allowed Custom Color to keep up with surging demand for silicone edge graphics for retail signage and display, exhibition signage and other applications.

Custom Color’s digital print operators have experience with several different DFEs, but have found the Fiery proServer offers efficient functionality that reduces mistakes and helps ensure high quality. ‘Our VUTEk FabriVU printers and our new VUTEk HS all run on Fiery,’ Lecus said. ‘The upside for us is their usability. The Fiery proServer DFEs are very intuitive, and they are doing a great job for us.’

|

LOCAL DISTRIBUTOR |