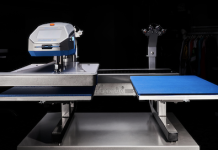

Summa has announced its Corrugated Tool, a new tool that is ideal for cutting corrugated boards precisely. Summa’s tool range is ever-expanding, providing even more solutions for the types of materials users can cut and for the cutting techniques available.

The Corrugated Tool is developed to cut corrugated board. There’s a lot involved in creating the perfect tool to handle these materials. When a knife makes contact with the corrugated board, it hits the materials at various angles, due to the natural air gaps in the material. This dulls the blades fast and increases the chances of tearing.

The new Corrugated Tool has a unique design that eliminates these air gaps by compressing the material. This makes the board nearly solid in shape and easy to cut. This not only prevents tearing, it also makes the cutting process faster, smoother and significantly more efficient.

Corrugated Vs Oscillating

Oscillating tools, like the Pneumatic Oscillating Tool (POT) and Electric Oscillating Tool (EOT) in Summa’s product range, deliver cutting quality. However, there are some key differences between these tools and the Corrugated Tool that could make all the difference for a user’s workflow.

The main advantage of the Corrugated Tool lies in its cutting motion. Unlike the up-and-down motion of an oscillating tool, the Corrugated Tool cuts in a single, straight line, up to 10 times faster. This efficiency makes it ideal for high-volume or time-sensitive projects.

The Corrugated Tool features a specially coated knife that enhances durability, extending its lifespan significantly. In contrast, oscillating tools do not have this coating, meaning the Corrugated Tool can save time and money on replacements in the long run.

While the Corrugated Tool is purpose-built for corrugated board, oscillating tools offer greater versatility. They can handle a wider range of materials, such as foam, Styrofoam, and paper-lined foamboard. If projects require cutting across multiple materials, an oscillating tool might be the better fit.

If designs involve intricate details or complex patterns, the Corrugated Tool excels in precision cutting. Its ability to handle both simple and detailed designs on corrugated board makes it a standout choice for specialised applications.

The tool comes with two different types of compression wheels to suit different applications. Depending on the application and/or when a smaller zone is required, users can switch to the narrow wheels.

Standard compression wheels are ideal for cutting materials up to 5mm thick. Narrow compression wheels are ideal for cutting materials up to 1.8mm thick.

Whether working with thick or thin corrugated materials, the tool adapts seamlessly to deliver consistent, high-quality results.

|

LOCAL DISTRIBUTOR |