Massivit 3D, along with market intelligence firm IDC, recently hosted a webinar featuring Massivit 3D customer and Media Resources owner Steve Gallow, as well as IDC Analyst Tim Greene, who has been researching the large format business for the last 20 years.

They highlighted the current top PSP business challenges (and practical tips to overcome them); and how print business Media Resources has been able to cut through fierce competition by incorporating large format 3D printing into its offering.

Particular emphasis was placed on sustainability, such as using fabric instead of vinyl, and paper instead of plastic. Greene also stated that 3D printing businesses need to be aware that different PSPs have different routes to market with different techniques; that there has been a big decline in PSPs over the years (possibly due to the increase of services offered in one single business). There is also a great need for them to adapt to ever-changing market conditions.

Some key industry trends Greene highlighted included:

Speed to market: this is driven by a demand for higher service levels and versioning, as well as increasing seasonality and complexity.

Fresh ideas: non-experts need fresh ideas to help them identify new products and capabilities.

Convergence: more businesses are demanding 3D printing services than ever before. Due to this increased competition, commercial printing establishments and revenues are declining. Many of these establishments are offering more services, and more commercial printers are moving into the large format space.

Challenges: maintaining profit margins; finding new sources of sales/revenues; keeping up with print buyer demands for price and quality; keeping up to date with technology/hardware solutions as well as finding good sales and production employees.

Advantages of large format 3D printing include:

• Unique patented technology.

• Geometric freedom.

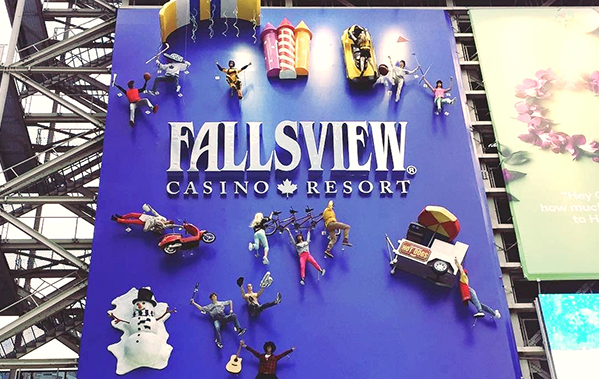

• Large size builds for trade shows, retail and marketing campaigns.

• Take advantage of customisation and decoration capabilities in large format printing shops.

• Work closely with brands and buyers.

• Find new customers.

Greene also said, ‘If we compare the retail value of large format business to that of 3D printing, the former is much bigger. However, the growth rate of 3D printing is six times higher than large format printing. 3D printing is the answer to the problems large format print service providers have.’

During the webinar, audience polls illustrated that price pressure is the biggest challenge for PSPs, i.e prices they are allowed to charge for billboards are dropping significantly. Additionally, audiences favoured new business capabilities over driving down costs, and most of those that partook in the webinar have looked into 3D printing as an extra part of their business.

Gallow, a Massivit 3D customer, was a pioneer in digital technology, who experienced success as one of the earlier users of the concept, but as the rest of the world embraced it, its value went down. As such he heeded the call to branch out his print services.

Gallow said he used to buy blocks of foam and carve them out by hand, which was not only expensive but also time consuming , before 3D printing was a even ‘a thing’. With 3D printing, geometric dimensions that are hard to design can now done be produced quickly and easily.

‘By adding 3D printing as a service to our business, our turnaround time has gone from three months to two-three weeks,’ said Gallow, ‘We now not only have new jobs and new customers, but new jobs from existing customers. In terms of marketing our services, we took advantage of Google and social media, and have acquired more leads due to being at the top of page searches.’

Gallow further stated that with 3D printing there is less weight as a print is hollow – unlike foam – and it is therefore easier to assemble, disassemble and transport. He also sometimes combines foam cutting with 3D printing and his business has penetrated the film and commercial industry. ‘Always see if your customers require 3D printing services,’ concluded Gallow.

MASSIVIT 3D www.massivit3d.com